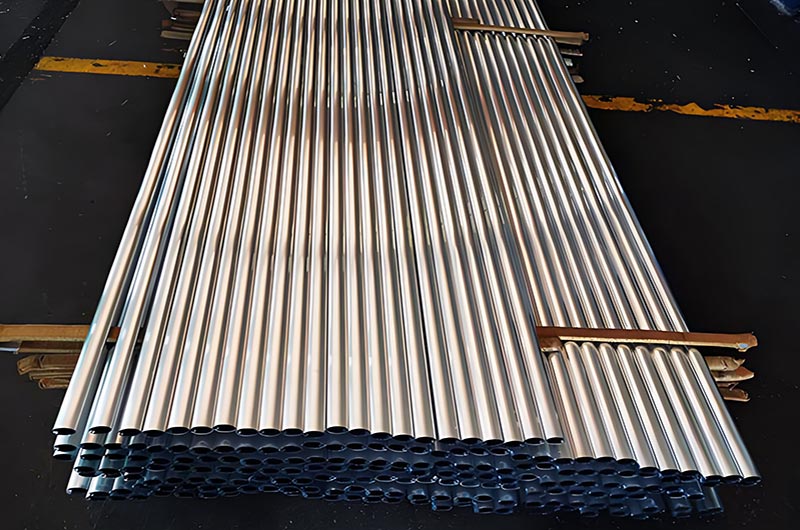

Aluminium tubular busbar is a conductor used in power systems for transmitting large currents, made of high-purity aluminium or aluminium alloys, typically in a round hollow tube structure.

Aluminium tubular busbars are made from high-purity aluminium or its alloys (e.g., 6061, 6063). Their tubular design optimizes the balance between material usage and performance, fully utilizing aluminium's lightweight, cost-efficiency, and corrosion resistance.

An aluminium tubular busbar is a hollow seamless conductor that serves as a solid connection point between a large current source (such as a power grid transmission line or transformer at a substation) and a load center. The tubular design combines high current-carrying capacity, excellent mechanical strength, and improved heat dissipation.

Aluminium Tubular Busbar Construction and Design

Aluminium tubular busbars, unlike traditional flat or solid busbars, feature a tubular design with a hollow cross-section. This configuration maximizes weight reduction while maintaining high rigidity and durability. The large surface area relative to the cross-section helps with effective heat dissipation, reducing temperature rise during operation.

Dimensions and Cross-sectional Area:

Typical specifications may include conductor diameter (e.g., Ø 120 mm) and wall thickness (e.g., 10 mm), resulting in a high cross-sectional area to achieve low resistance and efficient current flow.

Aluminium Tubular Busbar Electrical Properties

- Current Carrying Capacity: The cross-sectional area determines the capacity. Although the material of the tube is less than a solid rod of the same diameter, the skin effect in AC systems makes the tubular shape more efficient, as the current primarily flows near the surface.

- Skin Effect Mitigation: The conductor's geometry is aligned with current distribution to reduce AC resistance, thus minimizing losses.

- Voltage Drop: Due to effective surface utilization, the voltage drop is lower in high-frequency applications than in solid rods.

Aluminium Tubular Busbar Thermal Performance

The hollow tubular design of the aluminium tubular busbar enables efficient heat dissipation, reducing thermal losses and maintaining stable electrical performance even under heavy load.

- Heat Dissipation: The hollow core and increased surface area enhance cooling, reducing thermal stress and improving load handling.

- Thermal Expansion: Aluminium expands when heated; the tubular design can adapt to movement through strategic support spacing or flexible joints.

Aluminium Tubular Busbar Mechanical Advantages

| Advantage | Description |

| Mechanical Strength and Low Weight | Due to its tubular structure, the aluminium tubular busbar has superior rigidity compared to stranded conductors, allowing it to achieve longer spans with the same current-carrying capacity, reducing reliance on supporting structures. This feature reduces overall mechanical load, making installation more cost-effective, particularly suitable for long-span transmission systems. |

| Strength-to-Weight Ratio | The hollow structure of the aluminium tubular busbar provides higher rigidity and bending resistance compared to a solid busbar of the same mass. This feature makes it particularly suitable for long-span applications, showing significant advantages when reducing the number of supports while maintaining a low overall weight. |

| Seismic Resistance | Due to its round cross-section, the aluminium tubular busbar effectively reduces resonance when subjected to mechanical vibrations, thereby decreasing the risk of material fatigue. This makes it perform excellently in earthquake-prone areas or environments with strong equipment vibrations, improving the reliability and lifespan of transmission systems. |

Aluminium Tubular Busbar Main Materials

- Aluminium Alloys: Busbars are typically made from high-quality aluminium alloys (e.g., 6101, 6061, 6063, or 6Z63 specialized heat-resistant alloys). The selection of each alloy balances factors such as electrical conductivity, mechanical strength, and corrosion resistance.

- Standard Compliance: Busbars are produced according to international standards (e.g., IEC 60865, IEC 61597, IEC 61439, ASTM B241, and IEC 61936) to ensure they meet stringent safety and performance requirements.

Aluminium Tubular Busbar Advantages

- Lightweight yet Sturdy: Compared to traditional busbars, the tubular structure of the aluminium tubular busbar significantly reduces weight while maintaining high mechanical strength.

- Efficient Heat Dissipation: The large surface area of the tube helps evenly distribute the current and reduce hotspots.

- Corrosion Resistance: Aluminium alloys offer excellent corrosion resistance, helping to extend service life and reduce maintenance costs.

- Space Efficiency: Its design reduces the required installation footprint, thereby decreasing the number of supporting points and foundations needed.

- High Current Capacity: The hollow design aids heat dissipation, making it suitable for high-current applications.

- High Mechanical Strength: Strong bending resistance and wind vibration resistance.

- Lightweight: Aluminium tubular busbars are lighter and cost less than copper busbars.

Aluminium Tubular Busbar Applications

- Power Transmission and Substations: Aluminium tubular busbars are widely used as connecting conductors between power grid transmission lines and transformers at substations. They can also be used as jumper conductors and overcurrent devices in large current DC icing systems.

- High Current Circuits: Aluminium tubular busbars can handle large currents, making them ideal for generator busbars, transformer bus systems, and large electrical switching equipment applications.

- Infrastructure and Renewable Energy: These aluminium tubular busbars are essential components in modern distribution systems, increasingly used in renewable energy projects due to their durability and efficiency.

- High Current Environments: Substations, power plants, and industrial facilities.

- High Voltage Systems: Due to their smooth surface, they reduce corona discharge, which is crucial in high-voltage applications.

- Space-Constrained Installations: Easier wiring in confined spaces compared to flat bars.

Aluminium Tubular Busbar Advantages over Solid/Copper Busbars

| Advantages | Description |

| Cost-effectiveness | Aluminium tubular busbars, compared to copper busbars, are not only more economical in terms of material cost but also lighter in weight, reducing the cost of support structures. Since aluminium is usually much cheaper than copper, and its lower density allows for the use of less material under the same load conditions, it overall reduces construction and maintenance costs. Therefore, using aluminium tubular busbars is a significantly cost-effective choice. |

| Efficient Cooling | Aluminium tubular busbars, due to their hollow structure and larger surface area, have better heat dissipation compared to solid busbars. This allows aluminium tubular busbars to effectively release heat under high load conditions, preventing overheating and enhancing the stability and safety of power transmission. Their structural design also gives them superior cooling efficiency over solid busbars. |

| Environmentally Friendly | Aluminium tubular busbars have a higher recyclability, making them much more environmentally friendly compared to copper busbars. Aluminium can be effectively recycled and reused after use, reducing waste impact on the environment. The recycling process for aluminium is also simpler and more economical than copper, making aluminium tubular busbars an ideal green material choice. |

Aluminium Tubular Busbar Manufacturing Process

The manufacturing process uses advanced techniques such as seamless hot top casting, three-roll milling, and cold drawing. These processes produce busbars with a smooth surface, high dimensional accuracy, and consistent mechanical properties along their length.

- Extrusion: Aluminium is extruded into seamless tubes to ensure uniform thickness and structural integrity.

- Surface Treatment: Anodizing or coating (e.g., tin, silver) can be applied to enhance conductivity, corrosion resistance, or reduce oxidation.

Aluminium tubular busbars represent an advanced solution for high-current distribution. Their unique design, advanced manufacturing processes, and outstanding material performance make them an ideal choice for critical applications in power transmission, substations, and various industrial facilities. Whether used in traditional power grids or modern renewable energy systems, these busbars ensure reliable performance, enhancing safety, efficiency, and service life.

Limitations of Aluminium Tubular Busbars

- Lower conductivity compared to copper: equivalent current requires a larger cross-sectional area.

- Connection complexity: may require special fittings for terminations.

Selection and Maintenance of Aluminium Tubular Busbars

How to Choose the Right Model?

a. Model Selection

Current Capacity: Choose the cross-sectional size based on the system's maximum load current (e.g., Φ50×5, Φ80×6, etc.). For example:

- A 1000A load can select Φ60×5 aluminium tubular busbar.

- For loads above 4000A, choose Φ150×10 or larger cross-sections.

Voltage Level: For medium and low voltage (1kV~35kV), bare aluminium tubes are commonly used; for high voltage (110kV and above), insulation or shielding structures are required.

Environmental Adaptability:

- Outdoor/Humid environments: Select anti-corrosion coatings (e.g., anodizing, tin plating) or 6063 aluminium alloy.

- High salt fog areas: Prioritize 316 stainless steel supports.

b. Material Selection

- Pure Aluminium (1060/1070): High conductivity (≥61% IACS), suitable for general environments.

- Aluminium Alloys (6063/6061): 20%~30% strength improvement, suitable for large spans or high mechanical stress scenarios.

c. Supporting Components

- Fittings: Use hot-dip galvanized or copper-aluminium transition joints to avoid electrochemical corrosion.

- Insulators: For indoor use, epoxy resin is preferred; for outdoor use, silicone rubber or ceramic materials are needed.

What to Pay Attention to During Aluminium Tubular Busbar Use?

| Category | Specific Requirements |

| Installation Specifications | |

| Support Spacing | Should not exceed 2.5 meters (horizontal)/1.5 meters (vertical) to prevent sagging. |

| Bending Radius | ≥2 times the tube diameter to avoid mechanical damage. |

| Connection Handling | Apply conductive paste, tighten bolts to the standard torque (e.g., M12 bolts should be tightened to 40~50N·m). |

| Operation Monitoring | |

| Temperature Rise Control | Normal operation ≤70°C, infrared temperature measurement once every quarter. |

| Vibration Prevention | Install anti-vibration brackets in windy or equipment-adjacent areas. |

| Environmental Protection | |

| Chemical Protection | Avoid direct contact with acidic/alkaline substances, and regularly clean in chemical plants. |

| Snowy Areas | Design an inclined angle or install a snow-melting device. |

Installation Precautions for Aluminium Tubular Busbars

- Connectors: Special fixtures or flat ends/connection plates are required to ensure a safe connection.

- Support: Spacing should consider weight and thermal expansion.

- Insulation: Epoxy coatings or sleeves can be used to ensure safety and reduce arc flash.

How Often Should Aluminium Tubular Busbars Be Replaced?

| Category | Specific Requirements |

| Normal Lifespan | The design life is typically 20-30 years, but actual lifespan is affected by the following factors: |

| Harsh Environment | In harsh environments such as chemical areas or coastal zones, assessment is needed every 10-15 years. |

| High Load | When operating current exceeds 80% of rated current, lifespan is reduced by 20%-30%. |

| Replacement Indicators | |

| Electrical Performance | DC resistance exceeds 10% or insulation resistance is <1MΩ/km. |

| Mechanical Damage | Deformation of the tube exceeds 5%, cracks deeper than 1mm. |

| Corrosion Condition | Wall thickness is reduced by more than 15% from the original thickness. |

Safety Features

- Reduces Corona Effect: The smooth tubular surface minimizes ionization in high-voltage devices.

- Fire Resistance: Non-combustible and self-extinguishing.

Aluminium tubular busbars provide the best combination of electrical efficiency, mechanical strength, and cost savings, making them an ideal choice for modern power distribution systems. Their design addresses key challenges such as thermal management, skin effect, and installation flexibility, making them the best choice for high current and high voltage applications.