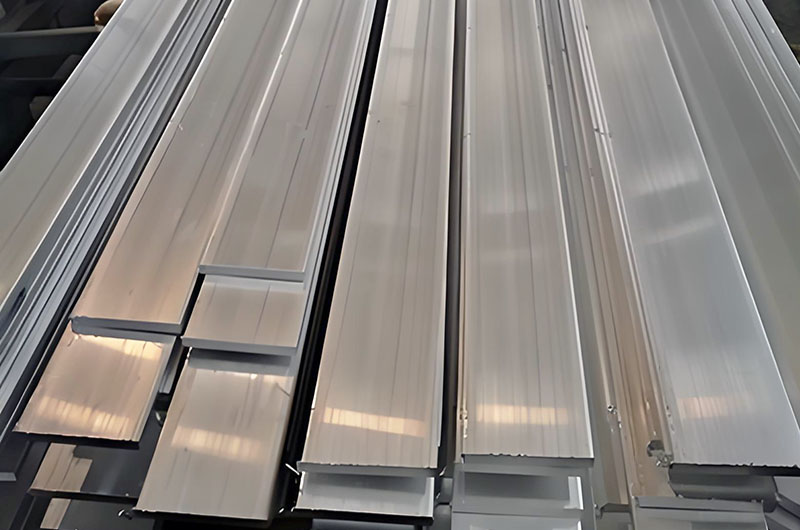

6101-T61 aluminum bus bar is a high-performance electrical conductor widely used in industries that require a balance of strength, conductivity, and corrosion resistance.

6101 T61 aluminum bus bar is made from a heat-treatable alloy in the 6101 series. This alloy is designed to offer a balanced combination of moderate mechanical strength and high conductivity, making it particularly suitable for power distribution and other electrical applications. It is widely used as a cost-effective, lightweight alternative to copper in busbar systems.

6101 T61 Aluminum Bus Bar Material Composition and Temper

- Alloy: 6101 aluminum, belonging to the Al-Mg-Si (aluminum-magnesium-silicon) series, optimized for electrical applications.

- Temper (T61): Achieved through solution heat treatment followed by an artificially under-aged process. This process enhances electrical conductivity while maintaining moderate mechanical strength, making it ideal for applications where current-carrying efficiency is prioritized over extreme rigidity.

Alloy Composition:

The 6101 alloy consists primarily of aluminum (approximately 98%), with controlled additions of magnesium (0.35–0.8%), silicon (0.3–0.7%), and copper (0–0.1%), along with trace elements such as chromium, manganese, and boron. This carefully formulated composition achieves an excellent balance between strength and conductivity.

Temper – T61:

The "T61" designation indicates that the material has undergone solution heat treatment followed by aging. This temper provides:

- Enhanced electrical conductivity: Typically around 59% of the International Annealed Copper Standard (IACS).

- Moderate strength: While the mechanical strength of T61 is lower than T6, it is optimized for applications where high conductivity is critical.

6101 T61 Aluminum Bus Bar Characteristics

6101 T61 Aluminum Bus Bar Conductivity

59% IACS (International Annealed Copper Standard), with a volumetric conductivity close to 60% of copper. However, due to aluminum’s lower density, the weight-based conductivity is 200% compared to copper (146).

6101 T61 Aluminum Bus Bar Mechanical Properties

Moderate strength: Sufficient to handle mechanical stresses in busbar applications while still allowing for bending and forming.

Formability and weldability: Extruded bus bars can be easily shaped into custom forms and are compatible with common welding methods such as TIG and MIG, supporting various installation options.

- Tensile strength: ≥103 MPa

- Yield strength: ≥55 MPa

- Elongation: Not explicitly specified for T61, but similar alloys in T6 temper exhibit an elongation of 15%.

6101 T61 Aluminum Bus Bar Thermal Performance

Excellent thermal conductivity: Ensures efficient heat dissipation during high-current flow, which is essential for preventing overheating.

- Thermal conductivity: 222 W/m·K (excellent heat dissipation).

- Coefficient of thermal expansion: 21.7 µm/m·°C (stable under temperature fluctuations).

6101 T61 Aluminum Bus Bar Corrosion Resistance

- Exhibits excellent resistance to environmental degradation, making it reliable for outdoor and high-humidity applications.

- Corrosion resistance: Resistant to moisture, acids, alkalis, and most corrosive environments, making it suitable for outdoor or high-humidity applications.

6101 T61 Aluminum Bus Bar Specifications, Sizes, and Tolerances

Specifications:

| EC 6101 t61 aluminum busbar specification | |

| Temper | T61 |

| Shape | Rectangular, round, or tubular profiles; rectangular is the most common for effective current distribution. |

| Requirements for surface quality | Smooth surface without defects such as burrs and spots; The surface is clean, dust-free, oil-free, and free of other impurities; The oxide layer is uniform, dense, and has good corrosion resistance; |

| Surface treatment | Anodizing, electroplating, spraying, etc. Usually aluminum plating includes: silver, tin, nickel |

| Insulation treatment | Insulation coating: powder coating, epoxy resin coating or insulation paint coating, etc. Insulating sleeve: polyvinyl chloride (PVC), heat shrink tubing, or silicone rubber, etc. |

| Processing | Stamping, bending, drilling, tapping, polishing, etc. |

| Product packaging | When delivering according to length, it should be packaged in bundles and boxes, and when delivering according to quality, it should be packaged in discs, circles, or bundles. |

| Test | Conductivity testing, temperature rise testing, bending testing, salt spray test (e.g., ASTM B117), etc. |

| Standard | ASTM B317: Standard specification for aluminum bus conductors. |

| IEC 60439: Low-voltage switchgear and controlgear assemblies. | |

Standard Dimensions:

- Thickness: 2–20 mm (0.08–0.79 inches).

- Width: 30–130 mm (1.18–5.12 inches).

- Length: Customizable, up to 12 meters.

Tolerances:

- Thickness: ±0.008 inches

- Width: ±0.024 inches

- Length: -0/+0.125 inches (for specific products).

6101 T61 Aluminum Bus Bar Bending and Formability

Minimum Bending Radius:

0.125–0.500 inch thickness: 1× thickness

0.501–0.749 inch thickness: 2× thickness

0.750–1.000 inch thickness: 3× thickness.

Formability: Easy to machine, weld (TIG/MIG), and shape into custom profiles (e.g., round, R-corner edges).

6101 T61 Aluminum Bus Bar Surface and Insulation Treatments

Surface Treatments:

Anodizing, electroplating (tin/silver/nickel), or powder coating to enhance corrosion resistance and aesthetics.

| Treatment Type | Description |

| Anodizing Treatment | The anodizing treatment of 6101 T61 aluminum bus bar forms an aluminum oxide layer on the surface, enhancing corrosion resistance and wear resistance while improving insulation, making it suitable for humid or high-pollution environments. |

| Electroplating Treatment | The electroplating treatment of 6101 T61 aluminum bus bar can use tin, silver, or nickel plating to improve conductivity and oxidation resistance. Tin plating enhances weldability, silver plating increases conductivity, and nickel plating enhances wear resistance and high-temperature durability. |

| Powder Coating | The powder coating of 6101 T61 aluminum bus bar uses epoxy or polyester powder with excellent insulation properties, making it safer in electrical systems while providing additional UV resistance and chemical corrosion resistance. |

Insulation Options:

Epoxy coating, PVC tubing, or heat shrink tubing to prevent short circuits.

| Treatment Type | Description |

| Epoxy Coating | The epoxy coating on 6101 T61 aluminum bus bar forms a uniform, strong electrical insulation layer that effectively prevents short circuits and corona discharge while enhancing moisture and chemical resistance. |

| PVC Tube Insulation | The PVC tube insulation of 6101 T61 aluminum bus bar provides flexible and durable protection, preventing mechanical damage and ensuring long-term reliability in humid or high-pollution environments. |

| Heat Shrink Tube Insulation | The heat shrink tube insulation of 6101 T61 aluminum bus bar uses heat shrink material that tightly adheres to the bus bar surface after heating, providing excellent electrical insulation while enhancing wear resistance and moisture protection. |

6101 T61 Aluminum Bus Bar Advantages

- Lightweight and Cost-Effective: Although the unit-area conductivity of 6101 T61 aluminum is lower than that of copper, its lighter weight and lower cost make it an attractive choice. Properly sized 6101 bus bars can provide comparable performance.

- Design Flexibility: With multiple available tempers (T6, T61, T63, T64, T65), designers can select the optimal balance of strength, conductivity, and formability for specific applications.

- Strong Corrosion Resistance: Highly suitable for environments requiring long-term exposure to moisture and corrosive elements.

6101 T61 Aluminum Bus Bar Applications

| Application Fields | Description |

| Power Distribution | 6101 T61 aluminum bus bar is widely used in power distribution applications such as substations, switchgear, and distribution panels. Due to its excellent conductivity and corrosion resistance, this aluminum bus bar effectively transmits high current, ensuring the stability and efficiency of power distribution systems. Its lightweight nature also helps reduce installation and maintenance costs, making it suitable for large-scale power facilities. |

| Industrial and Commercial Equipment | 6101 T61 aluminum bus bar is used in industrial and commercial equipment, particularly in control panels, generators, and transformers, as a core electrical connection component. Its good conductivity and durability make it a reliable current transmission solution for these devices, ensuring stable power supply under high load conditions. Additionally, its low weight and easy machinability simplify the installation process. |

| Transportation and Aerospace | 6101 T61 aluminum bus bar plays an important role in transportation and aerospace applications, especially in electric vehicles (EVs), railway systems, and lightweight electrical systems in aircraft. The lightweight nature and excellent conductivity of this aluminum bus bar make it highly suitable for systems requiring efficient power transmission. In electric vehicles and railway systems, the 6101 T61 aluminum bus bar helps optimize battery management and electrical power systems while reducing overall weight and energy consumption; in aircraft applications, it provides a lightweight and efficient power transmission solution. |

| Renewable Energy Systems | 6101 T61 aluminum bus bar is used in renewable energy systems, such as battery packs and solar panel connections, to provide reliable power transmission. Its corrosion resistance and excellent conductivity ensure stable and reliable electrical connections between batteries and solar panels, even in harsh environments. Particularly in battery packs, using aluminum bus bars not only improves power efficiency but also reduces equipment weight, enhancing overall system performance. |

Comparison of 6101 T61 Aluminum Bus Bar with Other Alloys

- Compared to 6063: 6101-T61 has higher strength but slightly lower conductivity (6063: ~55% IACS).

- Compared to 1350: 6101-T61 has better creep resistance and mechanical durability, but 1350 has higher pure conductivity (61–62% IACS).

Standards and Certifications of 6101 T61 Aluminum Bus Bar

- Complies with ASTM B317, IEC 60105, and ISO 209-1 standards.

- Quality testing includes conductivity inspection, bending tests, and resistance measurement.

6101-T61 aluminum bus bar is a versatile solution suitable for electrical systems requiring lightweight, corrosion-resistant, and highly efficient conductors. Its balance of mechanical and electrical performance makes it a preferred alternative to copper in industries such as power distribution, transportation, and renewable energy.

Manufacturing and Finishing of 6101 T61 Aluminum Bus Bar

Production Process:

Bus bars are typically produced through extrusion, forming rectangular (or flat) cross-section profiles. This process adheres to strict dimensional tolerances as specified in standards such as ASTM B317.