6101 aluminum busbar is a conductor made of 6101 aluminum alloy (a material composed of magnesium and silicon). It is designed to balance high conductivity with enhanced mechanical strength. This alloy is widely used in power distribution, switchgear, battery systems, and other high-current applications where weight reduction and cost efficiency are critical.

Although the conductivity of 6101 is slightly lower than that of 1350 (a nearly pure aluminum alloy), it has higher yield strength and better creep resistance.

6101 aluminum busbar Alloy Composition

6101 EC (Electrical Conductor) is an aluminum alloy optimized for electrical applications.

- Primary Elements: Aluminum (Al), Magnesium (Mg), Silicon (Si).

- Trace Elements: Tight control over impurities (e.g., iron, copper) to enhance conductivity.

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | B | Standard(wt%) |

| 6101 | 0.30-0.70 | ≦0.50 | ≦0.10 | ≦0.03 | 0.35-0.80 | ≦0.03 | ≦0.1 | ≦0.06 | EN573-3-2007 |

6101 aluminum busbar Available Tempers

Common Temper: T6 (solution heat-treated and artificially aged), providing a balance of strength and conductivity.

| Temper | Description |

| 6101-T6 Aluminum Busbar | Achieved through solution heat treatment and artificial aging, the 6101-T6 aluminum busbar provides maximum mechanical strength and is widely used in high-performance busbar applications, such as power distribution systems and industrial busbar systems, where high strength and good conductivity are required. |

| 6101-T61 Aluminum Busbar | In an over-aged state, the 6101-T61 aluminum busbar offers better conductivity at the cost of ductility. This busbar is suitable for applications that require high conductivity, such as transformer windings and large power grid systems, helping to reduce energy losses. |

| 6101-T63 Aluminum Busbar | As an intermediate state, the 6101-T63 aluminum busbar balances conductivity and strength, making it suitable for applications that require moderate strength and formability, such as switchgear components and electrical panels. |

| 6101-T64 Aluminum Busbar | In a partially annealed state, the 6101-T64 aluminum busbar maximizes formability and provides the highest conductivity. This busbar is typically used in applications that require complex bending and forming, such as battery connectors and flexible electrical joints. |

| 6101-T65 Aluminum Busbar | Offering medium conductivity with controllable tensile strength and yield strength, the 6101-T65 aluminum busbar enhances bend repeatability, making it particularly suitable for busbar systems that require precise installation tolerances and repeatable bending, such as precision power distribution equipment. |

6101 Aluminum Busbar Electrical Properties

- Electrical Conductivity: Typically around 55–60% IACS, allowing it to efficiently carry high currents while maintaining low losses.

- Better than Copper: Lighter weight, lower cost, but equivalent current capacity may require a larger cross-sectional area.

6101 Aluminum Busbar Mechanical Properties

- Mechanical Strength: Higher yield strength and better creep resistance compared to higher-purity aluminum alloys like 1350. This makes it more robust in structural and thermal cycling applications.

- Ductility: 6101 has medium ductility, allowing it to be formed and shaped during installation.

- Comparison: Conductivity is higher than 6061 aluminum, but mechanical strength is slightly lower.

- Formability and Machinability: 6101 alloy is easy to extrude and machine, and can be formed into various shapes (flat, right angles, round or R corners) with a smooth surface and minimal edge burrs.

- Weldability: Compatible with standard welding techniques like TIG and MIG, but heat input may affect local strength.

| Alloy | Temper | Yield Strength Rp0.2(Mpa) | Tensile Strength Rm(Mpa) | Conductivity %IACS | Bending |

| 6101 | T63 | ≥150 | ≥185 | ≥56 | 90°1t |

| T64 | ≥55 | ≥105 | ≥59.5 | 90°1t |

6101 aluminum busbar Thermal Properties

- Thermal Expansion: 23.6 µm/m·°C (higher than copper), thus thermal cycling must be considered in the design.

- Melting Point: ~655°C, suitable for most electrical environments.

- Heat Dissipation: Good thermal conductivity (~180 W/m·K) helps control heat buildup.

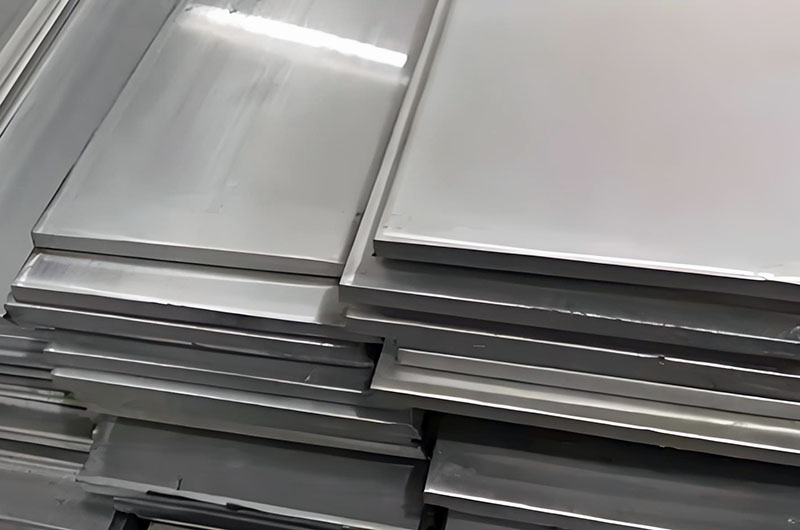

6101 aluminum busbar Dimensions and Specifications

| Item | Specifications/Range |

| Thickness | 2 - 20 mm |

| Width | 30 - 130 mm |

| Length | 3 m, 6 m, 12 m (custom cutting available) |

| Standard Compliance | ASTM B317, IEC 60105, ISO 209-1, etc. |

| Design Options | Right angle, rounded corners, R-corner busbar, smooth edges (no burrs), high dimensional accuracy |

6101 aluminum busbar Surface Treatment

- Anodizing or Powder Coating: Used to enhance corrosion resistance and provide a uniform, smooth surface.

- Plating: Options include tin plating, silver plating, or nickel plating—this further improves surface oxidation resistance and helps reduce contact resistance.

| Product Type | Description |

| Tin-Plated 6101 Aluminum Busbar | Tin-plated 6101 aluminum busbars offer excellent oxidation resistance and corrosion resistance, performing well in humid or harsh environments. The tin plating enhances the busbar's welding performance and improves connection reliability, making them widely used in switchgear, transformer connections, and power distribution systems to ensure long-term stable electrical performance. |

| Silver-Plated 6101 Aluminum Busbar | Silver-plated 6101 aluminum busbars have extremely low contact resistance and excellent electrical conductivity, making them ideal for high-performance electrical applications. The silver plating improves the busbar's heat resistance and reduces energy losses, making them widely used in high-frequency electrical equipment, avionics, telecommunications, and precision electrical connections. |

| Nickel-Plated 6101 Aluminum Busbar | Nickel-plated 6101 aluminum busbars have excellent corrosion resistance, high-temperature resistance, and mechanical strength, making them suitable for extreme environments and high-temperature electrical systems. The nickel plating provides good wear resistance and ensures reliable electrical contact under harsh conditions, commonly used in rail transport, marine power systems, and specialized industrial equipment. |

6101 aluminum busbar Manufacturing and Processing

- Extrusion and Rolling: Busbars are typically produced through extrusion or rolling, allowing for high-volume production of standard or custom sizes.

- Processing and Finishing: Post-extrusion processes include cutting, bending, and surface finishing to meet precise design requirements.

- Connection Methods: Welding (TIG/MIG), bolt connections, or clamps; using compatible connectors to avoid electrochemical corrosion.

6101 aluminum busbar Standards and Compliance

- ASTM B317: Specifies the requirements for extruded aluminum busbars.

- IEC 60439: Governs low-voltage switchgear components.

- UL Certification: Usually required to ensure the safety of electrical systems.

6101 aluminum busbar Applications

6101 EC aluminum busbars have a wide range of uses and are suitable for various electrical and industrial applications:

| Application Area | Description |

| Distribution | 6101 EC aluminum busbars are primarily used in switchgear, substations, and distribution panels as efficient conductive paths, providing stable power transmission for industrial and commercial facilities. Their excellent conductivity and corrosion resistance ensure long-term reliable operation, while reducing the overall system weight, improving ease of installation and maintenance. |

| Power Plants and Stations | 6101 EC aluminum busbars serve as the main conductors for large current and high-power transmission, effectively reducing energy loss and improving the efficiency of power systems. Due to their superior conductivity and heat resistance, these busbars are widely used in thermal power plants, hydropower plants, nuclear power generation, and other high-power transmission scenarios. |

| Battery Systems and Electric Vehicle Charging | 6101 EC aluminum busbars perform excellently in battery systems and electric vehicle charging due to their excellent mechanical properties and lightweight characteristics, making them an ideal choice for battery packs and electric vehicle charging stations. These busbars can withstand high current loads and provide efficient power transmission, ensuring the stable operation of battery management systems and charging infrastructure. |

| Industrial and Aerospace | 6101 EC aluminum busbars are favored in the industrial and aerospace fields due to their excellent strength-to-weight ratio and good formability. They have wide applications in aerospace, electrical equipment manufacturing, and other engineering applications where weight is a concern. Their corrosion resistance and high conductivity make them an ideal material for aircraft power distribution systems, satellite components, and high-end industrial equipment. |

| Renewable Energy | 6101 EC aluminum busbars play a key role in renewable energy applications, being widely used in solar power plants, wind turbines, and battery storage systems. Due to their high conductivity and resistance to environmental corrosion, these busbars ensure the efficient and stable operation of new energy systems, reducing energy transmission losses and improving overall energy utilization. |

Advantages of 6101 Aluminum Busbar Over Other Materials

- Cost-Effective: The material cost is lower than copper, and it is about 70% lighter than copper, reducing installation and transportation costs.

- Lightweight: The density is approximately 1/3 that of copper, making installation and structural support easier.

- Mechanical Properties: Enhanced yield strength and creep resistance compared to high-purity aluminum alloys (such as 1350) provide better performance under mechanical stress and thermal cycles.

- Design Flexibility: 6101 busbars come in a variety of tempers and shapes, which can be customized according to specific electrical and mechanical design requirements.

- Environmental and Economic Benefits: Aluminum is more cost-effective and recyclable, helping to reduce environmental impact.

6101 aluminum and copper current carrying capacity comparison table

| Ampacity Conversion Chart | Copper C110 | 30° C Rise | 50° C Rise | 65° C Rise | Aluminum 6101 | 30° C Rise | 50° C Rise | 65° C Rise | ||||

| Flat Bar Size in Inches | Sq. In | Circ Mils Thousands | Weight Per Ft in Lb. | DC Resistance at 20° C, Microhms/Ft | 60 Hz Ampacity Amp* | Weight Per Ft in Lb. | DC Resistance at 20° C, Microhms/Ft | 60 Hz Ampacity Amp** | ||||

| 1/16 x 1/2 | 0.0312 | 39.7 | 0.121 | 264 | 103 | 136 | 157 | 0.037 | 494 | 58 | 76 | 88 |

| 1/16 x 3/4 | 0.0469 | 59.7 | 0.181 | 175 | 145 | 193 | 225 | 0.055 | 327 | 81 | 108 | 126 |

| 1/16 x 1 | 0.0625 | 79.6 | 0.242 | 132 | 187 | 250 | 285 | 0.073 | 247 | 105 | 140 | 160 |

| 1/16 x 1 1/2 | 0.0938 | 119 | 0.362 | 87.7 | 270 | 355 | 410 | 0.110 | 164 | 151 | 199 | 230 |

| 1/16 x 2 | 0.125 | 159 | 0.483 | 65.8 | 345 | 460 | 530 | 0.146 | 123 | 193 | 258 | 297 |

| 1/8 x 1/2 | 0.0625 | 79.6 | 0.241 | 132 | 153 | 205 | 235 | 0.073 | 247 | 86 | 115 | 132 |

| 1/8 x 3/4 | 0.0938 | 119 | 0.362 | 87.7 | 215 | 285 | 325 | 0.110 | 164 | 120 | 160 | 182 |

| 1/8 x 1 | 0.125 | 159 | 0.483 | 65.8 | 270 | 360 | 415 | 0.146 | 123 | 151 | 202 | 232 |

| 1/8 x 1 1/2 | 0.188 | 239 | 0.726 | 43.8 | 385 | 510 | 590 | 0.220 | 82 | 216 | 286 | 330 |

| 1/8 x 2 | 0.25 | 318 | 0.966 | 32.9 | 495 | 660 | 760 | 0.293 | 62 | 277 | 370 | 426 |

| 1/8 x 2 1/2 | 0.312 | 397 | 1.210 | 26.4 | 600 | 800 | 920 | 0.365 | 49 | 336 | 448 | 515 |

| 1/8 x 3 | 0.375 | 477 | 1.450 | 21.9 | 710 | 940 | 1100 | 0.439 | 41 | 398 | 526 | 616 |

| 1/8 x 3 1/2 | 0.438 | 558 | 1.690 | 18.8 | 810 | 1100 | 1250 | 0.512 | 35 | 454 | 616 | 700 |

| 1/8 x 4 | 0.5 | 636 | 1.930 | 16.5 | 900 | 1200 | 1400 | 0.585 | 31 | 504 | 672 | 784 |

| 3/16 x 1/2 | 0.09375 | 119 | 0.362 | 87.7 | 195 | 260 | 300 | 0.110 | 164 | 109 | 146 | 168 |

| 3/16 x 3/4 | 0.141 | 179 | 0.545 | 58.4 | 270 | 360 | 415 | 0.165 | 109 | 151 | 202 | 232 |

| 3/16 x 1 | 0.188 | 239 | 0.726 | 43.8 | 340 | 455 | 520 | 0.220 | 82 | 190 | 255 | 291 |

| 3/16 x 1 1/2 | 0.281 | 358 | 1.090 | 29.3 | 480 | 630 | 730 | 0.329 | 55 | 269 | 353 | 409 |

| 3/16 x 2 | 0.375 | 477 | 1.450 | 21.9 | 610 | 810 | 940 | 0.439 | 41 | 342 | 454 | 526 |

| 3/16 x 2 1/2 | 0.469 | 597 | 1.810 | 17.5 | 740 | 980 | 1150 | 0.549 | 33 | 414 | 549 | 644 |

| 3/16 x 3 | 0.562 | 715 | 2.170 | 14.6 | 870 | 1150 | 1350 | 0.658 | 27 | 487 | 644 | 756 |

| 3/16 x 3 1/2 | 0.656 | 835 | 2.530 | 12.5 | 990 | 1300 | 1500 | 0.768 | 23 | 554 | 728 | 840 |

| 3/16 x 4 | 0.75 | 955 | 2.900 | 11 | 1100 | 1450 | 1700 | 0.878 | 21 | 616 | 812 | 952 |

| 1/4 x 1/2 | 0.125 | 159 | 0.483 | 65.8 | 240 | 315 | 360 | 0.146 | 123 | 134 | 176 | 202 |

| 1/4 x 3/4 | 0.188 | 239 | 0.726 | 43.8 | 320 | 425 | 490 | 0.220 | 82 | 179 | 238 | 274 |

| 1/4 x 1 | 0.25 | 318 | 0.966 | 32.9 | 400 | 530 | 620 | 0.293 | 62 | 224 | 297 | 347 |

| 1/4 x 1 1/2 | 0.375 | 477 | 1.450 | 21.9 | 560 | 740 | 880 | 0.439 | 41 | 314 | 414 | 482 |

| 1/4 x 2 | 0.5 | 637 | 1.930 | 16.5 | 710 | 940 | 1100 | 0.585 | 31 | 398 | 526 | 616 |

| 1/4 x 2 1/2 | 0.625 | 796 | 2.410 | 13.2 | 850 | 1150 | 1300 | 0.731 | 25 | 476 | 644 | 728 |

| 1/4 x 3 | 0.75 | 955 | 2.900 | 11 | 990 | 1300 | 1550 | 0.878 | 21 | 554 | 728 | 868 |

| 1/4 x 3 1/2 | 0.875 | 1110 | 3.380 | 9.4 | 1150 | 1500 | 1750 | 1.024 | 18 | 644 | 840 | 980 |

| 1/4 x 4 | 1 | 1270 | 3.860 | 8.23 | 1250 | 1700 | 1950 | 1.170 | 15 | 700 | 952 | 1092 |

| 1/4 x 5 | 1.25 | 1590 | 4.830 | 6.58 | 1500 | 2000 | 2350 | 1.463 | 12 | 840 | 1120 | 1316 |

| 1/4 x 6 | 1.5 | 1910 | 5.800 | 5.49 | 1750 | 2350 | 2700 | 1.755 | 10 | 980 | 1316 | 1512 |

| 3/8 x 3/4 | 0.281 | 368 | 1.090 | 29.3 | 415 | 550 | 630 | 0.329 | 55 | 232 | 308 | 353 |

| 3/8 x 1 | 0.375 | 477 | 1.450 | 21.9 | 510 | 680 | 790 | 0.439 | 41 | 286 | 381 | 442 |

| 3/8 x 1 1/2 | 0.562 | 715 | 2.170 | 14.6 | 710 | 940 | 1100 | 0.658 | 27 | 398 | 526 | 616 |

| 3/8 x 2 | 0.75 | 955 | 2.900 | 11 | 880 | 1150 | 1350 | 0.878 | 21 | 493 | 644 | 756 |

| 3/8 x 2 1/2 | 0.938 | 1190 | 3.620 | 8.77 | 1050 | 1400 | 1600 | 1.097 | 16 | 5.88 | 784 | 896 |

| 3/8 x 3 | 1.12 | 1430 | 4.350 | 7.35 | 1200 | 1600 | 1850 | 1.310 | 14 | 672 | 896 | 1036 |

| 3/8 x 3 1/2 | 1.31 | 1670 | 5.060 | 6.38 | 1350 | 1800 | 2100 | 1.533 | 12 | 756 | 1008 | 1176 |

| 3/8 x 4 | 1.5 | 1910 | 5.8 | 5.49 | 1500 | 2000 | 2350 | 1.755 | 10 | 840 | 1120 | 1316 |

| 3/8 x 5 | 1.88 | 2390 | 7.26 | 4.38 | 1800 | 2400 | 2800 | 2.2 | 8 | 1008 | 1344 | 1568 |

| 3/8 x 6 | 2.25 | 2860 | 8.69 | 3.66 | 2100 | 2800 | 3250 | 2.633 | 7 | 1176 | 1568 | 1820 |

| 1/2 x 1 | 0.5 | 637 | 1.93 | 16.5 | 620 | 820 | 940 | 0.585 | 31 | 347 | 459 | 526 |

| 1/2 x 1 1/2 | 0.75 | 955 | 2.9 | 11 | 830 | 1100 | 1250 | 0.878 | 21 | 465 | 616 | 700 |

| 1/2 x 2 | 1 | 1270 | 3.86 | 8.23 | 1000 | 1350 | 1550 | 1.17 | 15 | 560 | 756 | 868 |

| 1/2 x 2 1/2 | 1.25 | 1590 | 4.83 | 6.58 | 1200 | 1600 | 1850 | 1.463 | 12 | 672 | 896 | 1036 |

| 1/2 x 3 | 1.5 | 1910 | 5.8 | 5.49 | 1400 | 1850 | 2150 | 1.755 | 10 | 784 | 1036 | 1204 |

| 1/2 x 3 1/2 | 1.75 | 2230 | 6.76 | 4.7 | 1550 | 2100 | 2400 | 2.048 | 9 | 868 | 1176 | 1344 |

| 1/2 x 4 | 2 | 2550 | 7.73 | 4.11 | 1700 | 2300 | 2650 | 2.34 | 8 | 952 | 1288 | 1484 |

| 1/2 x 5 | 2.5 | 3180 | 9.66 | 3.29 | 2050 | 2750 | 3150 | 2.925 | 6 | 1148 | 1540 | 1764 |

| 1/2 x 6 | 3 | 3820 | 11.6 | 2.74 | 2400 | 3150 | 3650 | 3.51 | 5 | 1344 | 1764 | 2044 |

| 1/2 x 8 | 4 | 5090 | 15.5 | 2.06 | 3000 | 4000 | 4600 | 4.68 | 4 | 1680 | 2240 | 2576 |

- **Source: Copper Development Organization https://www.copper.org/applications/electrical/busbar/bus_table1.html

- **Source: Aluminum Association https://www.aluminum.org/sites/default/files/aecd13.pdf

Note: Ratings depend upon configuration, air flow, ambient temp, etc. The values depicted are an approximation. Controlled testing is always required to validate.

Other considerations:

- Forming the busbar (aluminum has a tendacy to crack with very tight radius)

- Electroplating the busbar (white rust on aluminum, oxidation is an issue with aluminum)

- Configuration of the busbar (vertical or horizontal configuration)

HC Aluminum Common sizes of 6101 aluminum busbar

6101 Right Angle Aluminum Busbar

| Thickness A (in) | Width B (in) | Estimated Weight per lb/ft |

| 1/8 | 0.375 | 0.055 |

| 1/8 | 0.500 | 0.074 |

| 1/8 | 0.625 | 0.090 |

| 1/8 | 0.750 | 0.110 |

| 1/8 | 0.875 | 0.127 |

| 1/8 | 1.000 | 0.149 |

| 1/8 | 1.250 | 0.184 |

| 1/8 | 2.000 | 0.299 |

| 1/8 | 2.500 | 0.371 |

| 1/8 | 4.000 | 0.599 |

| 3/16 | 0.375 | 0.084 |

| 3/16 | 0.500 | 0.112 |

| 3/16 | 0.625 | 0.140 |

| 3/16 | 0.750 | 0.168 |

| 3/16 | 0.875 | 0.187 |

| 3/16 | 1.000 | 0.222 |

| 3/16 | 2.000 | 0.442 |

| 1/4 | 0.500 | 0.149 |

| 1/4 | 0.750 | 0.209 |

| 1/4 | 1.000 | 0.284 |

| 1/4 | 1.250 | 0.359 |

| 1/4 | 1.500 | 0.434 |

| 1/4 | 2.000 | 0.584 |

| 1/4 | 2.500 | 0.734 |

| 1/4 | 3.000 | 0.884 |

| 1/4 | 3.250 | 0.959 |

| 1/4 | 4.000 | 1.184 |

| 1/4 | 4.500 | 1.334 |

| 1/4 | 5.000 | 1.484 |

| 1/4 | 6.000 | 1.784 |

| 1/4 | 7.000 | 2.084 |

| 1/4 | 8.000 | 2.384 |

| 3/8 | 0.625 | 0.277 |

| 3/8 | 1.25 | 0.527 |

| 3/8 | 2 | 0.864 |

| 3/8 | 2.5 | 1.120 |

| 3/8 | 3 | 1.134 |

| 3/8 | 4 | 1.764 |

| 3/8 | 5 | 2.214 |

| 3/8 | 6 | 2.664 |

| 3/8 | 8 | 3.596 |

| 1/2 | 0.75 | 0.385 |

| 1/2 | 1.5 | 0.896 |

| 1/2 | 2 | 1.196 |

| 1/2 | 3 | 1.796 |

| 1/2 | 4 | 2.396 |

| 1/2 | 5 | 2.996 |

| 1/2 | 6 | 3.596 |

| 1/2 | 8 | 4.796 |

| 1/2 | 10 | 5.996 |

| 3/4 | 1 | 0.884 |

| 3/4 | 4 | 3.455 |

| 3/4 | 5 | 4.495 |

| 1 | 1.25 | 1.498 |

| 1 | 8 | 9.535 |

| 1 | 10 | 11.996 |

| 1 | 12 | 14.364 |

Rounded Corners 6101 Aluminum Busbar

| Thickness A (in) | Width B (in) | Radius R (in) | Estimated Weight per lb/ft |

| 1/8 | 0.375 | 0.031 | 0.055 |

| 1/8 | 0.5 | 0.016 | 0.074 |

| 1/8 | 0.5 | 0.031 | 0.074 |

| 1/8 | 0.625 | 0.062 | 0.09 |

| 1/8 | 0.75 | 0.031 | 0.11 |

| 1/8 | 0.875 | 0.062 | 0.127 |

| 1/8 | 1 | 0.031 | 0.149 |

| 1/8 | 1.25 | 0.062 | 0.184 |

| 1/8 | 2 | 0.031 | 0.299 |

| 1/8 | 2.5 | 0.031 | 0.371 |

| 1/8 | 4 | 0.031 | 0.599 |

| 3/16 | 0.375 | 0.031 | 0.084 |

| 3/16 | 0.5 | 0.031 | 0.112 |

| 3/16 | 0.625 | 0.031 | 0.14 |

| 3/16 | 0.75 | 0.016 | 0.169 |

| 3/16 | 0.75 | 0.031 | 0.168 |

| 3/16 | 0.875 | 0.094 | 0.187 |

| 3/16 | 1 | 0.062 | 0.222 |

| 3/16 | 2 | 0.094 | 0.442 |

| 1/4 | 0.5 | 0.031 | 0.149 |

| 1/4 | 0.75 | 0.125 | 0.209 |

| 1/4 | 1 | 0.125 | 0.284 |

| 1/4 | 1.25 | 0.125 | 0.359 |

| 1/4 | 1.5 | 0.125 | 0.434 |

| 1/4 | 2 | 0.125 | 0.584 |

| 1/4 | 2.5 | 0.125 | 0.734 |

| 1/4 | 3 | 0.125 | 0.884 |

| 1/4 | 3.25 | 0.125 | 0.959 |

| 1/4 | 4 | 0.125 | 1.184 |

| 1/4 | 4.5 | 0.125 | 1.334 |

| 1/4 | 5 | 0.125 | 1.484 |

| 1/4 | 6 | 0.125 | 1.784 |

| 1/4 | 7 | 0.125 | 2.084 |

| 1/4 | 8 | 0.125 | 2.384 |

| 3/8 | 0.625 | 0.062 | 0.277 |

| 3/8 | 1.25 | 0.188 | 0.527 |

| 3/8 | 2 | 0.062 | 0.895 |

| 3/8 | 2 | 0.187 | 0.864 |

| 3/8 | 2.5 | 0.062 | 1.12 |

| 3/8 | 3 | 0.187 | 1.314 |

| 3/8 | 5 | 0.187 | 2.214 |

| 3/8 | 4 | 0.187 | 1.764 |

| 3/8 | 6 | 0.187 | 2.664 |

| 3/8 | 8 | 0.062 | 3.596 |

| 1/2 | 0.75 | 0.250 | 0.385 |

| 1/2 | 1.5 | 0.062 | 0.896 |

| 1/2 | 2 | 0.062 | 1.196 |

| 1/2 | 3 | 0.062 | 1.796 |

| 1/2 | 4 | 0.062 | 2.396 |

| 1/2 | 5 | 0.062 | 2.996 |

| 1/2 | 6 | 0.062 | 3.596 |

| 1/2 | 8 | 0.062 | 4.796 |

| 1/2 | 10 | 0.062 | 5.996 |

| 3/4 | 1 | 0.125 | 0.884 |

| 3/4 | 4 | 0.375 | 3.455 |

| 3/4 | 5 | 0.062 | 4.495 |

| 1/1 | 1.25 | 0.031 | 1.498 |

| 1/1 | 8 | 0.25 | 9.535 |

| 1/1 | 10 | 0.062 | 11.996 |

| 1/1 | 12 | 0.188 | 14.364 |

Usage Notes

- Cross-sectional dimensions: Larger than copper under equivalent current, but the space/weight savings often justify this.

- Thermal management: Ensure adequate spacing and ventilation to handle expansion.

- Connector compatibility: Use anti-oxidation compounds or bimetallic strips when connecting to copper.

6101 EC aluminum busbars are a comprehensive conductor choice for modern electrical systems. By combining medium conductivity with excellent mechanical properties and outstanding formability, it meets the demanding requirements of high current and high reliability applications. Whether used in power distribution, battery systems, or industrial installations, its design flexibility and cost advantages make it a competitive alternative to copper and other aluminum alloys.

6101 EC aluminum busbars are a high-performance solution for modern electrical systems, offering the best balance of conductivity, strength, and cost-efficiency. Its use is particularly beneficial in large-scale and renewable energy projects where weight and sustainability are key factors. Proper design and installation practices ensure reliability and longevity in various operating environments.