Due to its lightweight nature, good conductivity, and ease of processing, 6063 aluminum busbar is an ideal choice in medium- and high-voltage power distribution fields. Although its strength is slightly lower than 6061, its overall performance holds a significant position in the power industry, especially for applications requiring a balance of cost and efficiency.

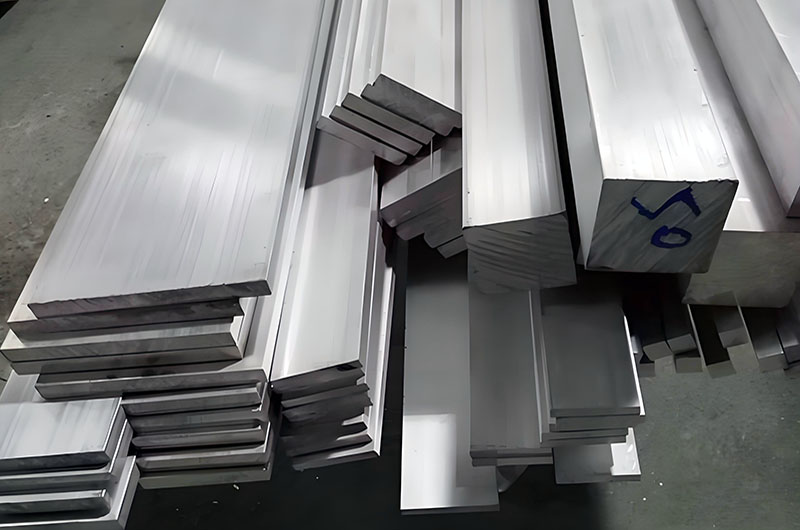

6063 aluminum busbar is a conductive metal component primarily used for power distribution. It is manufactured from 6063 aluminum alloy, a member of the 6000 series, known for its excellent extrudability, smooth surface finish, and corrosion resistance. These properties make it particularly well-suited for transformers, switchgear, substation applications, and decorative architectural busbars.

Specification of HC Aluminum 6063 Electrical Aluminum Busbar

| EC 6063 Aluminum Busbar Specifications | |

| Temper | T4, T5, T6, T52 |

| Shape | Rectangular, round, or tubular profiles; rectangular is the most common for effective current distribution. |

| Surface Quality Requirements | Smooth surface without burrs, spots, or defects; clean surface free of dust, oil, or other impurities; uniform and dense oxidation layer with excellent corrosion resistance. |

| Surface Treatment | Anodizing, electroplating, spraying, etc. Common aluminum plating includes silver, tin, and nickel. |

| Insulation Treatment | Insulation coatings: powder coating, epoxy resin coating, or insulating varnish. Insulation sleeves: PVC, heat-shrink tubing, or silicone rubber. |

| Processing | Stamping, bending, drilling, tapping, polishing, etc. |

| Product Packaging | When delivered by length, it should be packed in bundles or boxes. When delivered by weight, it should be packed in coils, rolls, or bundles. |

| Testing | Conductivity testing, temperature rise testing, bending testing, salt spray test (e.g., ASTM B117), etc. |

| Standards | ASTM B221 (extruded bars and profiles), IEC 61558 (power equipment), GB/T 5585.1-2018 (electrical aluminum busbars) |

Common Dimensions

- Thickness: 3 mm to 50 mm.

- Width: 20 mm to 300 mm.

- Length: Typically 6 meters, customizable.

HC 6063 EC-grade aluminum busbar complies with ASTM B317, ASTM B236, IEC 60105, ISO 209-1, 2, DIN EN 755-2, and EN 573-3 standards. 6063 aluminum busbar features excellent conductivity, high strength, good corrosion resistance, and a lightweight design.

6063 Aluminum Busbar Conductivity

Even with a conductivity level of approximately 28-34 MS/m, 6063 aluminum maintains effective electrical conductivity, despite being lower than that of copper. By designing busbars with a larger cross-sectional area, they can efficiently handle high-current loads.

6063 Aluminum Busbar Chemical Composition

6063 aluminum alloy belongs to the Al-Mg-Si series, with key components including magnesium (0.45-0.9%) and silicon (0.2-0.6%), with the remainder being aluminum and trace impurities (such as iron and copper). This composition balances strength, corrosion resistance, and workability.

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Remarks | Each | Total |

| 0.20- 0.60 | Max. 0.35 | Max. 0.10 | Max. 0.10 | 0.45- 0.9 | Max 0.10 | Max 0.10 | Max 0.10 | Max 0.05 | Max 0.15 |

6063 Aluminum Busbar Mechanical Properties

| Temper* | Thickness e** | Yield stress Rp0.2 (mpa) | Tensile strength Rm (mpa) | Elongation A[%] | Elongation A50mm [%] | Hardness ** HB |

| T4 | e<=25 | 65 | 130 | 14 | 12 | 45 |

| T5 | e<=3 | 130 | 175 | 8 | 6 | 55 |

|

3 |

110 | 160 | 7 | 5 | 50 | |

| T6 | e<=10 | 170 | 215 | 8 | 6 | 65 |

|

10 |

160 | 195 | 8 | 6 | 60 | |

| T66 | e<=10 | 200 | 245 | 8 | 6 | 75 |

|

10 |

180 | 225 | 8 | 6 | 70 |

6063 Aluminum Busbar Physical Properties

6063 alloy has a density of approximately 2.7 g/cm³ and excellent corrosion resistance due to its natural oxide layer. Its thermal conductivity (approximately 200-220 W/m·K) helps efficiently dissipate heat in high-power applications.

- Density: 2.69 g/cm³, lighter than copper, suitable for weight-sensitive applications.

- Electrical Conductivity: Approximately 55% IACS (International Annealed Copper Standard), superior to some aluminum alloys (such as 6061) but lower than pure aluminum (62% IACS).

- Thermal Conductivity: About 200 W/(m·K), providing excellent heat dissipation.

6063 Electrical Aluminum Busbar Surface Finishing

Busbars often undergo surface treatments such as anodizing, electroplating, or powder coating. These treatments not only enhance aesthetic appeal but also improve corrosion resistance, which is crucial for outdoor and industrial environments.

| Surface Treatment Type | Description |

| Anodized Aluminum Busbar | Anodized 6063 aluminum busbars form a hard aluminum oxide film on the surface, significantly enhancing corrosion resistance and surface hardness. This treatment is especially suitable for busbars used in high-humidity or chemical environments while also improving their appearance, making them more aesthetically pleasing and easy to maintain. |

| Tin-Plated Aluminum Busbar | Tin-plated 6063 aluminum busbars are covered with a uniform tin layer to improve oxidation resistance and solderability. Tin plating enhances durability in humid or corrosive environments and optimizes electrical contact characteristics, making them more stable and reliable in power and distribution systems. |

| Silver-Plated Aluminum Busbar | Silver-plated 6063 aluminum busbars offer superior electrical conductivity and oxidation resistance at contact points. The silver layer effectively reduces contact resistance, improves current transmission efficiency, and provides excellent corrosion resistance in high-temperature, high-humidity, or harsh industrial environments. These busbars are widely used in high-end electrical equipment and precision electronic systems. |

| Powder-Coated Aluminum Busbar | Powder-coated 6063 aluminum busbars undergo an electrostatic spray process to form a uniform and durable protective layer on the surface. This coating enhances weather resistance and chemical corrosion resistance while offering a wide range of color options, making it suitable for applications in construction, rail transportation, and outdoor power facilities where both appearance and durability are required. |

Comparison of 6063 Aluminum Busbar with Other Materials

| Properties | 6063 Aluminum Busbar | 6061 Aluminum Busbar | Copper Busbar |

| Electrical Conductivity (% IACS) | 55% | 43% | 100% |

| Density (g/cm³) | 2.69 | 2.71 | 8.96 |

| Tensile Strength (MPa) | 150-215 | 310 | 200-250 |

| Cost | Low | Medium | High |

| Typical Applications | Medium to high-current distribution | High-strength structural components | Ultra-high current demand |

6063 Aluminum Busbar Manufacturing and Processing

6063 aluminum is the most common alloy used for extrusion due to its excellent performance. In busbar production, the alloy is extruded into flat or customized profiles, with a maximum length of 6 meters. The width typically ranges from 10 mm to 200 mm, and the thickness varies from 0.15 mm to 40 mm. Maintaining width and thickness tolerances ensures reliable performance.

Production Process

- Extrusion Molding: 6063 aluminum busbars are primarily manufactured through the hot extrusion process, where heated aluminum billets are extruded through a die to achieve specific cross-sectional shapes (such as rectangular or channel profiles). Its excellent extrusion performance allows for the production of complex-section busbars.

- Heat Treatment: Typically, the T5 (air-cooled quenching) or T6 (water-cooled quenching + artificial aging) process is used to enhance strength and hardness.

6063 Electrical Aluminum Busbar Weldability and Machinability

6063 aluminum is highly weldable (especially with TIG welding) and easy to machine. Its excellent cold workability allows bending and forming into complex profiles without cracking, which is a key requirement for busbars that need to conform to various installation configurations.

6063 Electrical Aluminum Busbar Applications

- Power Systems: Used for conductive connections in transformers, switchgear, and distribution boxes.

- New Energy: Current transmission in photovoltaic inverters, energy storage systems, and electric vehicle charging stations.

- Industrial Equipment: Busbar design for frequency converters, motors, and welding machines.

- Building Electrical Systems: Lightweight solutions for high-rise building distribution systems.

Advantages of 6063 Aluminum Busbar

- Cost-effectiveness and Lightweight: Compared to copper busbars, 6063 aluminum offers weight and cost advantages. Although aluminum has a lower conductivity than copper, this can be compensated for by increasing the cross-sectional area.

- Corrosion Resistance: The natural oxide layer formed on 6063 aluminum provides excellent protection against corrosion, making it ideal for harsh environments.

- Conductivity and Heat Dissipation: Its high electrical and thermal conductivity make it suitable for high-current transmission while also facilitating heat dissipation.

- Ease of Processing: It can be adapted to different installation requirements through secondary processing such as cutting, drilling, and bending. The alloy's high extrudability and good weldability allow for customized shapes and sizes, enabling engineers to optimize busbar designs for specific applications.

- Aesthetic Appeal: Its smooth surface finish makes it particularly attractive for visible architectural applications, where both performance and appearance are essential.

Common sizes of HC aluminum electrical aluminum busbar

| Dimensions (Width × Thickness, mm) | Cross-sectional Area (mm²) | Theoretical Current Carrying Capacity (A) | Recommended Current Carrying Capacity (A) |

| 15 × 2 | 30 | 50 – 80 | ~65 |

| 15 × 3 | 45 | 80 – 110 | ~95 |

| 20 × 2 | 40 | 60 – 90 | ~75 |

| 20 × 3 | 60 | 100 – 150 | ~125 |

| 20 × 5 | 100 | 150 – 200 | ~175 |

| 25 × 3 | 75 | 90 – 120 | ~105 |

| 25 × 4 | 100 | 150 – 200 | ~175 |

| 30 × 4 | 120 | 150 – 180 | ~165 |

| 30 × 5 | 150 | 200 – 250 | ~225 |

| 30 × 8 | 240 | 250 – 300 | ~275 |

| 35 × 5 | 175 | 220 – 270 | ~245 |

| 35 × 8 | 280 | 280 – 330 | ~305 |

| 40 × 5 | 200 | 250 – 300 | ~275 |

| 40 × 8 | 320 | 300 – 350 | ~325 |

| 40 × 10 | 400 | 300 – 350 | ~325 |

| 50 × 8 | 400 | 300 – 350 | ~325 |

| 50 × 10 | 500 | 350 – 400 | ~375 |

| 50 × 12 | 600 | 350 – 400 | ~375 |

| 60 × 12 | 720 | 400 – 450 | ~425 |

| 70 × 15 | 1050 | 500 – 600 | ~550 |

| 80 × 15 | 1200 | 550 – 650 | ~600 |

| 100 × 20 | 2000 | 800 – 1000 | ~900 |

Notes:

- "Cross-sectional Area" is based on width × thickness (simplified calculation, actual value may be influenced by profile shape and processing techniques);

- "Theoretical Current Carrying Capacity" is a reference range, with values derived from conventional design experience;

- "Recommended Current Carrying Capacity" is the commonly used middle value in engineering, and can be used as a reference indicator during design;

For actual use, please verify with specific product instructions and safety margins.

Precautions

- Installation: Avoid direct contact with copper (use transition joints) to prevent electrochemical corrosion.

- Maintenance: Regularly check the integrity of the oxide layer, and apply anti-corrosion coatings in humid environments.

- Temperature Limitations: It is recommended that the long-term operating temperature does not exceed 90°C, with short-term tolerance up to 150°C.

6063 aluminum busbars stand out in power distribution systems. It combines moderate strength, excellent corrosion resistance, ease of manufacturing, and aesthetic versatility, making it an ideal choice not only in electrical applications but also in architectural and decorative environments. Whether used in transformers or as part of a building frame, 6063 aluminum busbars offer a reliable, cost-effective, and environmentally friendly solution to modern engineering challenges.