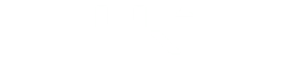

6061 aluminum busbar is a conductive metal strip made of 6061 aluminum alloy, primarily used in power transmission, equipment connections, and other applications.

6061 aluminum busbar, with its lightweight, moderate conductivity, and high strength properties, is widely used in power and new energy industries. Selection should consider conductivity requirements, budget, and environmental conditions, with cross-sectional area compensation if needed. Its overall performance surpasses pure aluminum and some aluminum alloys, making it an ideal choice for medium and low voltage applications.

6061 aluminum busbar is a lightweight and durable electrical conductor made of precipitation-hardened aluminum alloy, balancing good mechanical strength and moderate electrical conductivity. This makes it an ideal choice for power distribution in switchgear, distribution panels, and transformer components. This T6 tempered alloy not only offers enhanced tensile strength and durability but also excellent corrosion resistance (thanks to its natural oxide layer and optional surface treatments), while being easy to fabricate, with customizable shapes and sizes to optimize space and thermal management.

6061 Aluminum Busbar Information

6061 Aluminum Busbar Composition and Alloy Characteristics

- Base Material: The alloy consists of approximately 95.9–98.6% aluminum, with magnesium (0.8–1.2%) and silicon (0.4–0.8%) as its primary alloying elements.

- Heat Treatment: Common tempers include 6061-T6, where the material undergoes solution heat treatment and artificial aging, providing high mechanical strength and improved conductivity.

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Remarks | Each | Total |

| 0.40- 0.80 | Max. 0.7 | 0.15- 0.40 | Max. 0.15 | 0.8- 1.2 | 0.04- 0.35 | Max 0.25 | Max 0.15 | Max 0.05 | Max 0.15 |

6061 Aluminum Busbar Mechanical Properties

- Strength: In the T6 temper, the typical yield strength is approximately 240 MPa, and the tensile strength ranges from 290–310 MPa.

- Formability: Despite its moderate strength, 6061 is well known for its good weldability, machinability, and ability to be bent or stamped, making it highly suitable for customized busbar designs.

| Temper* | Thickness e** | Yield stress Rp0.2 (mpa) | Tensile strength Rm (mpa) | Elongation A[%] | Elongation A50mm [%] | Hardness ** HB |

| T4 | e<=25 | 110 | 180 | 15 | 13 | 65 |

| T6 | e<=5 | 240 | 260 | 9 | 7 | 85 |

|

5 |

240 | 260 | 10 | 8 | 85 |

6061 Aluminum Busbar Physical Properties

- Density: 2.69 g/cm³, offering a significant lightweight advantage.

- Melting Point Range: 580–650°C

6061 Aluminum Busbar Machining Performance

Machinability

- Easy to cut, drill, and stamp, suitable for precision machining.

- Cutting lubrication is necessary to reduce tool wear.

Weldability

- Suitable for TIG/MIG welding, but hot cracking should be avoided (4043 welding wire is recommended).

- Post-weld solution treatment (530°C quenching + artificial aging) is required to restore strength.

Forming Process

- Excellent cold bending performance, with a recommended bending radius ≥ 2 times the thickness.

- Hot rolling process can improve surface finish.

6061 Aluminum Busbar Electrical Conductivity

- Conductivity: 43% IACS (International Annealed Copper Standard). While it is less conductive than copper, it is superior to ordinary steel and slightly lower than pure aluminum (approximately 62% IACS). This level is sufficient for many medium-to-high current applications.

- Electrical Resistivity: Approximately 3.94×10⁻⁸ Ω·m.

- Application Scenarios: Suitable for medium-to-low current loads; increasing cross-sectional area can compensate for lower conductivity.

6061 Aluminum Busbar Thermal Performance

Thermal Capacity: Aluminum has a higher heat storage capacity than copper, meaning it can absorb and dissipate heat more effectively, which helps manage surge currents and overload conditions.

6061 Aluminum Busbar Characteristics

- High Strength: In T6 temper, tensile strength ≥ 200 MPa, hardness above HB90.

- Corrosion Resistance: The surface aluminum oxide layer resists atmospheric corrosion, making it suitable for both indoor and outdoor environments.

- Machining Performance: Easy to cut, bend, and weld, making it ideal for complex structural formations.

- Electrical Conductivity: Conductivity of 56.5–60% IACS, suitable for electrical components.

6061 Aluminum Busbar Advantages

- Lightweight: Aluminum's lower density means that 6061 busbars are significantly lighter than copper busbars, reducing installation and support costs.

- Cost-Effective: Typically less expensive than copper, making it an ideal choice for many electrical applications.

- Versatility: Good machinability and ease of forming, drilling, or welding allow for various shapes and sizes to fit different designs.

- Corrosion Resistance: The inherent oxide layer, combined with optional surface treatments, enhances durability and long-term performance.

6061 Electrical Aluminum Busbar Applications

What Industries Use 6061 Aluminum Busbars?

6061 aluminum busbars are commonly used in:

- Power Distribution: Used as the main conductor in switchgear, distribution panels, and busways.

- Transformers and Power Converters: Its high heat capacity and sufficient conductivity make it suitable for handling fluctuating currents.

- Industrial and Commercial Facilities: Its lightweight and easy manufacturability allow for custom configurations and installations in confined spaces.

- Renewable Energy Systems: Frequently used in solar arrays and battery systems, where weight reduction is beneficial.

What Are Its Applications in Power Transmission?

| Application | Description |

| 6061 Aluminum Busbar in Power Transmission | 6061 aluminum busbars are used in power transmission systems, connecting substations, distribution equipment, and transmission lines. With good conductivity, mechanical strength, and corrosion resistance, they serve as key conductive components. |

| 6061 Aluminum Busbar for High and Low Voltage Equipment Connections | 6061 aluminum busbars are used for electrical connections in high and low voltage equipment, such as high-voltage switchgear, transformers, and bus ducts. Their lightweight and easy installation make them suitable for high-rise buildings and rail transit power supply. |

| 6061 Aluminum Busbar as a Copper Replacement to Reduce Cost and Weight | Compared to copper busbars, 6061 aluminum busbars are lighter and more affordable, reducing transportation and installation costs. They offer high economic benefits in large-scale power projects while meeting transmission performance requirements. |

| 6061 Aluminum Busbar Requires Tin Plating or Anti-Corrosion Coating to Enhance Oxidation Resistance | 6061 aluminum busbars require tin plating or an anti-corrosion coating to prevent oxidation, ensure stable contact resistance, and enhance durability in humid or corrosive environments. |

Is 6061 aluminum bus bar suitable for high-temperature environments?

High-Temperature Suitability

Long-term operating temperature ≤150°C, short-term tolerance up to 200°C (avoid prolonged high temperatures to prevent strength degradation).

6061 Electrical Aluminum Bus Bar Heat Treatment and Conditions

6061 aluminum bus bar is a preferred material in industrial, construction, and transportation sectors due to its high strength-to-weight ratio, corrosion resistance, and flexible machinability. Its various conditions (such as T6, T651) can be tailored for different applications, meeting high precision and durability requirements with customized specifications and surface treatments.

- T6 Condition: Solution heat-treated and artificially aged, significantly enhancing hardness and strength.

- T651 Condition: Pre-stretched to relieve internal stress, reducing machining deformation, suitable for precision machining applications.

| Product | Description |

| 6061-T6 Aluminum Bus Bar | 6061-T6 aluminum bus bar undergoes solution heat treatment and artificial aging, significantly enhancing hardness and strength, making it suitable for power and industrial applications with high mechanical load requirements. |

| 6061-T651 Aluminum Bus Bar | 6061-T651 aluminum bus bar is pre-stretched to relieve internal stress, reducing machining deformation, making it ideal for high-precision applications such as electrical components and structural supports. |

Corrosion and Oxidation Resistance

Natural Oxidation: Aluminum naturally forms a protective oxide layer, enhancing its corrosion resistance. For bus bar applications, surface treatments such as tin plating, nickel plating, or silver plating can further inhibit oxidation and ensure reliable electrical connections.

6061 Electrical Aluminum Bus Bar vs. Other Materials

6061 aluminum bus bar is a versatile, durable, and cost-effective power distribution solution. It combines moderate strength, good electrical and thermal performance, and ease of manufacturing, making it particularly useful in applications where weight reduction and cost efficiency are critical. Whether used in industrial environments or renewable energy systems, 6061 bus bar is a reliable alternative to heavier and more expensive materials.

What is the difference between 6061 and 6063 aluminum alloys?

6061 vs. 6063 Aluminum Alloys

| Properties | 6061 | 6063 |

| Strength | Higher (T6 condition) | Lower, but better ductility |

| Machinability | Suitable for precision machining | More suitable for extrusion forming |

| Applications | Structural components, conductive bus bars | Architectural profiles, heat sinks |

Comparison of Conductivity Between Copper Bus Bar and 6061 Aluminum Bus Bar

Copper vs. Aluminum Bus Bar Conductivity

- Conductivity: Copper (100% IACS) > Aluminum (61% IACS) > 6061 Aluminum (43% IACS).

- Cost: Aluminum bus bar costs only 1/3-1/2 of copper bus bar and is 60% lighter.

- Suitable Applications: High-current applications favor copper bus bars, while aluminum bus bars offer better cost-effectiveness in medium to low load applications.

Which material is more suitable for conductive bus bars?

Conductive Bus Bar Material Selection Recommendations

- Copper Bus Bar: Preferred for high-frequency/high-current applications (e.g., data centers).

- 6061 Aluminum Bus Bar: Ideal for industrial applications balancing strength and conductivity (e.g., renewable energy equipment).

Selection and Usage Considerations

How to choose the right model?

Selection Criteria

- Choose cross-sectional area based on current load (considering current-carrying capacity and temperature rise).

- Prefer T6 condition (artificial aging) for a balance of strength and conductivity.

What should be considered during use?

Usage Considerations

- Avoid direct contact with copper (use tin plating or transition pads to prevent galvanic corrosion).

- Regularly check for loose connections (aluminum creep may cause poor contact over time).

How to maintain and store it?

- Storage Environment: Dry and well-ventilated, relative humidity <60%, keep away from acidic or alkaline corrosive substances.

- Surface Treatment: If the oxide film is damaged, apply anti-corrosion coating (such as epoxy resin) promptly.