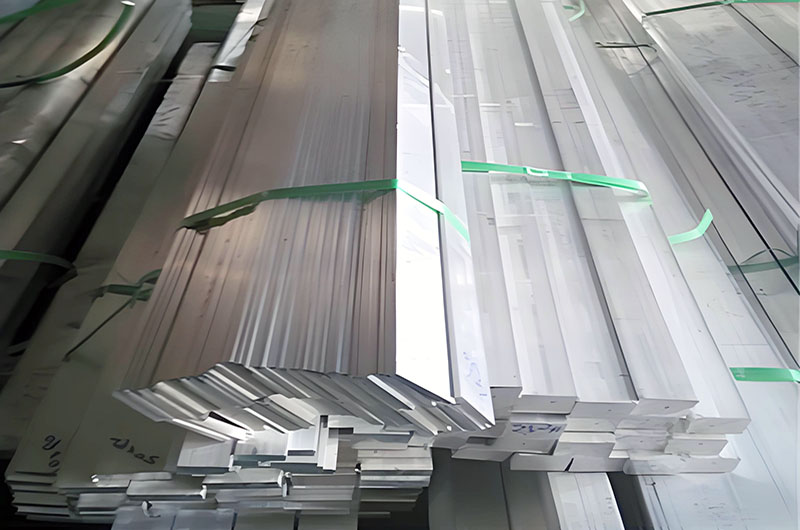

1100 aluminum busbar is a conductive component primarily used in power distribution systems, made from 1100 aluminum alloy.

1100 aluminum busbar is a conductor assembly made from 1100 aluminum alloy, which is a commercially pure grade containing approximately 99% aluminum. This high-purity alloy is selected for its excellent electrical and thermal conductivity, corrosion resistance, and outstanding formability. Although its mechanical strength is relatively low (and it cannot be strengthened by heat treatment), its excellent ductility and weldability make it an ideal choice for busbars used in power distribution systems.

Alloy 1100: Belonging to the 1000 series, it consists of 99% pure aluminum with minimal additives (e.g., 0.12% copper). This high purity ensures excellent electrical conductivity (~62% IACS), making it highly suitable for applications where efficient current flow is prioritized over mechanical strength.

1100 aluminum busbar Material Properties

1100 aluminum exhibits excellent electrical conductivity, thermal conductivity, corrosion resistance, and ductility but has low strength. Due to its electrical conductivity close to pure aluminum (~59% IACS), it is commonly used in power transmission, busway systems, transformer connections, and similar applications.

- Electrical and thermal conductivity: Due to its high aluminum content, 1100 alloy possesses high electrical conductivity and efficient heat dissipation, reducing temperature rise under load. This makes it highly suitable for busbar applications where efficient electrical and thermal management is crucial.

- High purity: Comprising approximately 99% aluminum, this alloy ensures very high electrical and thermal conductivity. This purity also means that the naturally formed oxide layer provides inherent corrosion resistance.

- Formability and ductility: 1100 aluminum cannot be strengthened through heat treatment; instead, it relies on cold working (such as stamping and bending) to achieve the desired shape. Its excellent ductility allows for forming various configurations with tight tolerances (typically around ±0.1 mm).

- Weldability: The soft and pure nature of 1100 aluminum makes it easy to weld, ensuring reliable joints in electrical components.

- Corrosion resistance: A naturally formed protective oxide layer makes it suitable for indoor and mild environmental conditions.

1100 aluminum busbar Specifications and Current-Carrying Capacity

What are the common specifications of 1100 aluminum busbar?

1100 aluminum busbar specifications are typically represented in the format Thickness × Width × Length, with common sizes as follows:

| Thickness (mm) | Width (mm) | Length (m) | Cross-sectional Area (mm²) |

| 5-50 | 20-300 | 1-6 (standard 6 meters) | 100-15, 000 |

Typical specification examples:

- 10×50×6000mm (Cross-sectional area 500mm²)

- 20×100×6000mm (Cross-sectional area 2000mm²)

- 30×150×6000mm (Cross-sectional area 4500mm²)

What is the current-carrying capacity?

The current-carrying capacity is influenced by environmental temperature, heat dissipation conditions, and installation methods. Below are estimated values under natural cooling conditions (ambient temperature 25℃):

| Cross-sectional Area (mm²) | Current-Carrying Capacity (A) | Applicable Scenarios |

| 100 | 150-200 | Small distribution cabinets, low-voltage circuits |

| 500 | 400-600 | Medium-sized busway systems, transformer connections |

| 1000 | 800-1000 | High-voltage power transmission, industrial power distribution |

| 2000 | 1200-1500 | Large substations, power generation equipment |

Note:

- In actual use, the safety factor (usually 0.7-0.8) should be considered, and derating is required in high-temperature environments.

- Forced air cooling or water cooling can increase the current-carrying capacity by approximately 20%-30%.

How to Select 1100 Aluminum Busbar Specifications Based on Requirements?

| Factor | Description |

| Current Requirement | Select the cross-sectional area based on the load current (refer to the current-carrying capacity table). For example, for a load current of 500A, a cross-sectional area of ≥300mm² is recommended (natural cooling). |

| Installation Space | In narrow spaces, choose aluminum busbars with a large width-to-thickness ratio (e.g., 10×100mm instead of 20×50mm). |

| Heat Dissipation Conditions | In enclosed environments or high-temperature scenarios, increase the cross-sectional area or enhance cooling measures. |

| Mechanical Strength | In environments with frequent vibrations, select thicker aluminum busbars (e.g., 30mm or more in thickness). |

| Cost Control | For the same cross-sectional area, aluminum busbars with a larger width-to-thickness ratio... |

1100 aluminum busbar is an economical and efficient conductive material. When selecting a model, balance current requirements, space constraints, and cost, and prioritize anodized products to extend service life.

Chemical composition of 1100 aluminum busbar

| Element | Composition(%) |

| Si | 0.95 |

| Fe | |

| Cu | 0.05-0.20 |

| Mn | 0.05 |

| Mg | - |

| Zn | 0.05 |

| Al | Remainder |

Mechanical property of 1100 aluminum busbar

| Temper | Yield strength MPa | Tensile strength MPa | Elongation | Hardness(HB) |

| F | 55 | 75 | 20 | 20 |

| O | 55 | 75 | 20 | 20 |

| H14 | 95 | 125 | 3 | 40 |

| H18 | 125 | 150 | 2 | 47 |

1100 Aluminum Busbar Applications

| Application | Description |

| Low Voltage Systems | 1100 aluminum busbar is widely used in low-voltage electrical systems, such as switchgear, transformer connections, and distribution panels. Due to its high conductivity and good corrosion resistance, it ensures efficient current transmission while reducing system energy consumption. In distribution panels, 1100 aluminum busbar can stably distribute power, ensuring the normal operation of equipment. |

| Battery Packs | 1100 aluminum busbar plays an important role in energy storage systems (such as lithium battery packs and backup power systems). Its excellent conductivity helps evenly distribute current among multiple battery cells, improving charging and discharging efficiency. Additionally, the lightweight nature of 1100 aluminum busbar makes it an ideal connecting material in energy storage systems, reducing overall weight while optimizing system performance. |

| Static Installations | 1100 aluminum busbar is suitable for static installation environments with minimal mechanical stress, such as control cabinets and wiring systems. In these applications, its high conductivity and corrosion resistance ensure long-term stable electrical connections. Additionally, due to the excellent workability of 1100 aluminum alloy, busbars can be easily shaped into different forms to accommodate complex electrical layouts. |

1100 Aluminum Busbar Standards and Compliance

- ASTM B317: Specifies the requirements for aluminum busbars, including conductivity and mechanical properties.

- IEC 60439: Low-voltage switchgear assembly and safety guidelines.

Comparison Between 1100 Aluminum Busbar and Copper Busbar

- Copper busbars have higher conductivity than aluminum busbars, but aluminum busbars are less dense and have better plasticity.

- Cost-effectiveness: Lower material cost and weight, making it ideal for large-scale installations.

- Lightweight: Reduces structural support requirements.

| Comparison Factor | Description |

| Conductivity Comparison | Copper busbars have better conductivity than 1100 aluminum busbars. For the same cross-sectional area, copper's conductivity is approximately 1.6 times that of aluminum. However, to achieve the same current-carrying capacity, aluminum busbars can compensate by increasing the cross-sectional area. While 1100 aluminum busbars have slightly lower conductivity, their lighter weight makes transportation and installation easier, making them a viable alternative to copper busbars in certain applications. |

| Material Properties | Copper busbars have higher conductivity, but aluminum busbars have a density that is only about one-third that of copper. This means that for the same volume, aluminum busbars weigh significantly less than copper busbars. Additionally, 1100 aluminum busbars have excellent plasticity and workability, making them easier to bend, punch, or form for specific power system needs. Although copper is stronger mechanically, aluminum busbars remain an ideal choice in applications where mechanical strength is not a primary concern. |

| Cost-effectiveness | The material cost of 1100 aluminum busbars is significantly lower than that of copper busbars. Additionally, due to its lower density, aluminum provides more volume for the same weight. This not only reduces overall procurement costs but also lowers transportation and installation expenses. In large-scale power system projects, using aluminum busbars can effectively reduce the project budget without significantly impacting system performance. |

| Weight Advantage | The lightweight nature of 1100 aluminum busbars makes them easier to install and reduces structural support requirements. In high-altitude installations or power systems requiring long-distance support, aluminum busbars can significantly reduce bracket and installation costs while decreasing the load on support structures, enhancing overall system safety and stability. |

Limitations of 1100 Aluminum Busbar

- Lower strength: Not suitable for environments with high vibration or mechanical stress.

- Oxidation risk: Surface oxidation can increase resistance; regular maintenance or coatings are recommended.

Comparison of 1100 Aluminum Busbar with Other Alloys

| Comparison | Description |

| 1100 Aluminum Busbar vs. 1350 (EC Grade) Aluminum Busbar | The conductivity of 1100 aluminum busbars is slightly lower than that of 1350 (EC grade) aluminum busbars, but it has superior formability. Due to the high purity of 1100 aluminum alloy (over 99%), it still provides good conductivity and offers an advantage in applications requiring complex bending or forming. Additionally, 1100 aluminum busbars have better corrosion resistance, making them suitable for humid or highly corrosive environments, whereas 1350 (EC grade) aluminum busbars are more commonly used in power transmission systems requiring extremely high conductivity. |

| 1100 Aluminum Busbar vs. 6061 Aluminum Busbar | 1100 aluminum busbars have significantly better conductivity and corrosion resistance than 6061 aluminum busbars, but they have lower mechanical strength. 6061 aluminum alloy is a heat-treatable alloy with higher strength and good mechanical properties, making it suitable for power systems requiring high mechanical load-bearing capacity. However, 1100 aluminum busbars offer superior conductivity and corrosion resistance, making them more competitive in low-voltage electrical systems or applications requiring stable current transmission. They are also easier to process and weld. |

1100 aluminum busbar performs excellently in static, low-stress electrical systems where optimal conductivity and corrosion resistance are required. It is suitable for cost-sensitive, high-current applications with minimal mechanical requirements. Proper design and installation practices ensure longevity and performance.

Installation and Handling of 1100 Aluminum Busbar

- Electrochemical Corrosion: When connecting with copper, use compatible connectors (such as tin-plated ones).

- Manufacturing: Due to its softness, it is easy to cut or shape but prone to scratches – handle with care.

Frequently Asked Questions

Q: How to choose between 1100 aluminum busbar and 6061 aluminum alloy busbar?

1100 is suitable for conductive applications, while 6061 has higher strength but lower conductivity (approximately 43% IACS), making it suitable for structural components.

Q: What to do if the aluminum busbar connection heats up?

Increase the contact area, use copper-aluminum transition connectors, and apply conductive paste.

Q: Can it replace copper busbars?

It can be a substitute, but for the same current-carrying capacity, the cross-sectional area needs to be increased by about 1.6 times. Space and cost considerations are necessary.

1100 aluminum busbar fully utilizes the inherent advantages of commercially pure aluminum: excellent conductivity, ease of manufacturing, and strong corrosion resistance. While its low strength limits its structural applications, its electrical and thermal properties make it an optimal choice for power distribution, thermal management, and precision-manufactured electrical components.