1070 aluminum busbar is a conductive metal component used in electrical systems for power distribution. Made from 1070 aluminum, these busbars are valued for their high purity and excellent electrical performance. They are used as main conductors in distribution panels, substations, battery packs, and transformer components, ensuring efficient collection, distribution, and transmission of electrical energy.

Introduction to 1070 Aluminum Busbar

Definition of 1070 Aluminum Busbar

1070 aluminum busbar is a conductive material made from 1070 industrial pure aluminum, with an aluminum content of no less than 99.7%, containing only trace amounts of impurities such as iron and silicon.

Due to its high purity, the electrical conductivity of 1070 aluminum busbar is close to that of pure aluminum, with a conductivity of approximately 61% IACS (International Annealed Copper Standard). It is widely used in power transmission and distribution systems and busbar trunks to meet high conductivity requirements.

Material Characteristics of 1070 Aluminum Busbar

1070 aluminum busbar belongs to the 1000 series of aluminum alloys, with an aluminum content of at least 99.7%, giving it excellent electrical conductivity and corrosion resistance. The high purity allows 1070 aluminum busbar to maintain good oxidation resistance in atmospheric, chemical, and marine environments, reducing maintenance costs. In addition, 1070 aluminum busbar has good ductility and workability, making it easy to bend, stamp, and weld, suitable for busbar systems of various sizes and complex shapes.

Application Areas of 1070 Aluminum Busbar

| Application Area | Specific Application | Advantages |

| Power Systems | Low Voltage Distribution | Used for switchgear, transformer winding connections, replacing copper busbars to reduce costs |

| Busbar Trunking | Lightweight design, suitable for commercial building distribution | |

| New Energy | Photovoltaic Inverters | DC side high-current connections |

| Energy Storage Systems | Low-resistance connections between battery clusters | |

| Transportation Field | Rail Transportation | Vehicle power busbars, reducing vehicle weight |

| Electric Vehicles | High-voltage battery busbars, optimizing energy efficiency | |

| Industrial Equipment | Welding Machines, Inverters | Used as internal conductive components |

1070 Aluminum Busbar Performance

Chemical Properties of 1070 Aluminum Busbar

Typical trace elements in 1070 aluminum include small amounts of iron, silicon, copper, manganese, etc., all of which are kept at very low levels (typically below 0.25%) to maintain its purity.

| Element | Component % |

| Si | Max. 0.20 |

| Fe | Max. 0.25 |

| Cu | Max. 0.04 |

| Mn | Max. 0.03 |

| Mg | Max. 0.03 |

| Cr | — |

| Zn | Max. 0.04 |

| Ti | Max. 0.03 |

| Others Individual | Max. 0.03 |

| Others Total | — |

| Al. | Min. 99.70 |

1070 Aluminum Busbar Physical Properties

- Density: 2.7 g/cm³, lighter than copper (about 30% of copper's weight).

- Melting Point: 660°C, moderate high-temperature resistance.

- Electrical Conductivity: Conductivity is approximately 35-38 MS/m, suitable for scenarios with high electrical conductivity requirements.

- Tensile Strength: 60-95 MPa (annealed state), can be increased to around 130 MPa after work hardening.

- Elongation: 30%-40% in the annealed state, good ductility, easy to process and form.

1070 Aluminum Busbar Mechanical and Processing Properties

- Mechanical Strength: While 1070 aluminum is not as strong as some structural alloys, it still provides sufficient tensile strength for many electrical applications.

- Formability and Machinability: 1070 alloy has excellent plasticity, allowing for easy stamping, bending, drilling, and welding (typically using 1100 filler wire for welding). This makes it highly adaptable to custom designs and complex busbar geometries.

Specifications and Current-Carrying Capacity of 1070 Aluminum Busbar

Specification Range of 1070 Aluminum Busbar

| Specification | Details |

| Material | 1070 Aluminum |

| Length | Up to 6 meters |

| Width | 10mm to 200mm |

| Thickness | 0.15mm to 40mm |

| Tolerance | +/- 0.1mm |

| Surface Treatment | Zinc, Nickel, Tin, Silver, etc. |

| Standards | ASTM B236 (Electrical conductor-grade aluminum) |

| IEC 60439 (Low-voltage switchgear and controlgear) |

Current-Carrying Capacity of Different Specifications of 1070 Aluminum Busbar

The current-carrying capacity of 1070 aluminum busbars is closely related to their specifications (cross-sectional area), ambient temperature, installation method (horizontal or vertical), cooling conditions, and other factors.

Relationship Between Current-Carrying Capacity and Specifications

The current-carrying capacity of 1070 aluminum busbars is mainly proportional to the cross-sectional area. Common specifications and their current-carrying capacity are as follows (ambient temperature 40°C, horizontal installation, natural cooling):

| Specification (Width×Thickness) | Cross-sectional Area (mm²) | Current-Carrying Capacity Range (A) |

| 50×5 mm | 250 mm² | 630-750 A |

| 60×6 mm | 360 mm² | 850-1000 A |

| 80×6 mm | 480 mm² | 1150-1300 A |

| 100×10 mm | 1000 mm² | 1550-1700 A |

| 120×10 mm | 1200 mm² | 1850-2000 A |

Note: The above data are estimates, and the actual current-carrying capacity should be adjusted according to specific working conditions. For example, vertical installation with better cooling can increase the current-carrying capacity by about 5%-10%.

Key Factors Affecting Current-Carrying Capacity

- Ambient Temperature: The current-carrying capacity needs to be reduced as the temperature increases. For example, if the ambient temperature rises from 40°C to 50°C, the current-carrying capacity should be multiplied by a correction factor of about 0.85.

- Cooling Conditions: Forced air cooling or water cooling can significantly improve the current-carrying capacity, for example, increasing it by 30%-50%.

- Surface Treatment: Oxidation or tin plating can reduce contact resistance, but may slightly affect cooling, so treatment should be balanced.

- Current Frequency: High-frequency current requires the selection of wider or thinner busbars due to the skin effect, which may reduce the current-carrying capacity by 10%-20%.

1070 Aluminum Busbar Selection Recommendations

Cross-Sectional Area Selection: The cross-sectional area should be calculated based on the load current and allowed temperature rise using the following formula:

I=K⋅S^0.7⋅T^0.39

Where, K is the material coefficient (approximately 0.6-0.65 for 1070 aluminum), S is the cross-sectional area (mm²), and T is the allowable temperature rise (°C).

- Alternative Options: If higher strength is needed, 6061 or 6063 aluminum alloys can be selected, but the electrical conductivity will decrease by about 20%, and the cross-sectional area will need to be increased to compensate.

- Connection Design: Avoid direct contact with copper. Use transition terminals or tin plating to prevent galvanic corrosion.

The current-carrying capacity of 1070 aluminum busbars should be evaluated based on a combination of specifications, environment, cooling, and other factors. When selecting, IEC standards or current-carrying capacity tables provided by suppliers can be referenced and dynamically adjusted based on actual working conditions. For high-precision requirements, it is recommended to verify through thermal simulation or actual testing to ensure safety and cost-effectiveness.

Surface Treatment Options for 1070 Aluminum Busbar

To improve performance and durability, 1070 aluminum busbars can be treated with various coatings (such as nickel plating, tin plating, or silver plating) to provide additional oxidation protection and enhance the mechanical appearance of the busbars.

| Surface Treatment Method | Characteristics and Advantages |

| Nickel-plated 1070 Aluminum Busbar | The 1070 aluminum busbar is subjected to electroplating nickel process, forming a dense nickel coating on the surface. After nickel plating, the 1070 aluminum busbar's oxidation resistance is enhanced, and it possesses high wear resistance and high-temperature resistance. It is suitable for high-temperature, high-humidity, and chemical environments such as industrial equipment, high-temperature power connections, and chemical plant power systems. |

| Tin-plated 1070 Aluminum Busbar | The 1070 aluminum busbar undergoes electroplating or hot-dip plating to form a uniform layer of tin on the surface. After tin plating, the 1070 aluminum busbar's weldability is improved, contact resistance is reduced, and oxidation is effectively prevented, ensuring long-term stable conductivity. It is suitable for electrical equipment, busbar connection terminals, distribution cabinets, etc. |

| Silver-plated 1070 Aluminum Busbar | The 1070 aluminum busbar is electroplated with silver, forming a highly conductive and oxidation-resistant silver coating on the surface. After silver plating, the contact resistance is significantly reduced, and it possesses excellent corrosion resistance and high-temperature performance. It is suitable for high-frequency current transmission, high-end electrical electronic devices, and aerospace applications. |

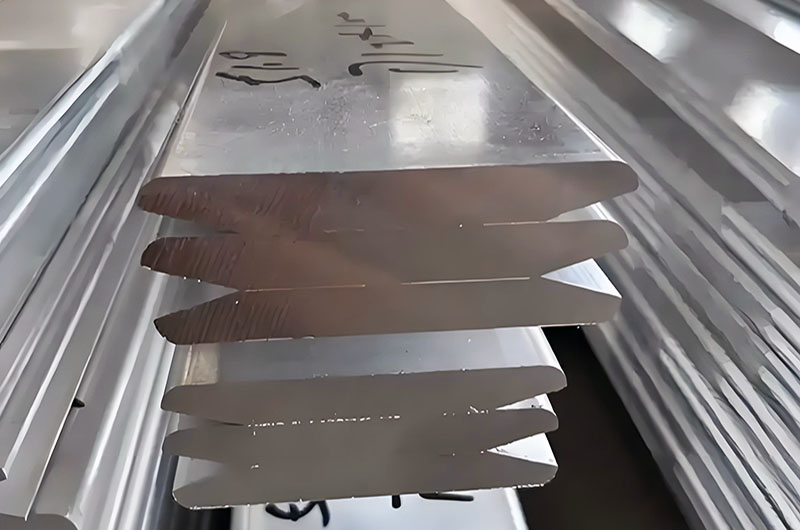

1070 Aluminum Busbar Manufacturing Process

1070 aluminum busbars are produced using various manufacturing techniques:

- Extrusion: Typically used for long and continuous profiles with rectangular or square cross-sections.

- Rolling (Flat Bar): Rolling can produce uniform flat products, which are very suitable for busbar applications.

- Machining and Forming: Techniques such as stamping, bending, drilling, and threading can customize the shape and size of busbars to meet specific engineering requirements.

These processes produce products in various lengths (usually up to 6 meters), widths (10-200 mm), and thicknesses (0.15-40 mm) to meet the needs of different electrical systems.

Production Process Flow

Process: Melting (adding trace amounts of boron/titanium for grain refinement) → Casting (flat ingots) → Hot rolling/cold rolling (thickness control) → Cutting (custom sizes) → Surface Treatment (tin plating, anodizing, or coating with insulating paint) → Quality Inspection (dimensions, conductivity).

Key Processing Points: Annealing treatment improves ductility to avoid brittleness caused by cold rolling; surface tin plating enhances oxidation resistance and reduces contact resistance.

Advantages of 1070 Aluminum Busbar

- Cost-effective: Aluminum is lighter and generally cheaper than copper, costing about one-third of copper, thereby reducing material and installation costs.

- High electrical performance: The high purity of 1070 aluminum ensures low resistivity and efficient power transmission.

- Easy to manufacture: The excellent formability of 1070 aluminum allows for a variety of manufacturing processes and customization, and it can be cold bent into complex shapes, reducing the number of joints.

- Corrosion resistance: The alloy's resistance to environmental degradation extends the lifespan of electrical equipment.

- Lightweight: Reduces the cost of support structures, especially suitable for high-altitude or mobile equipment.

Limitations of 1070 Aluminum Busbar

- Low strength: It may be necessary to increase thickness or add reinforcement ribs, which may offset the weight advantage.

- Thermal expansion: High coefficient of thermal expansion (23.1×10⁻⁶/°C), so long busbars need to be designed with expansion joints.

- Contact issues: Aluminum-copper connections require transition terminals to prevent galvanic corrosion.

Comparison of 1070 Aluminum Busbar and Copper Busbar

Copper busbars perform better in terms of conductivity and mechanical strength, but they are more expensive and heavier. 1070 aluminum busbars have advantages in cost and weight, but their conductivity and strength are slightly inferior. In practical applications, the best busbar material should be chosen based on specific needs and engineering requirements, considering all factors.

| Comparison Item | Copper Busbar | 1070 Aluminum Busbar |

| Conductivity | Copper has excellent conductivity, second only to silver, ensuring efficient and reliable power transmission. | 1070 aluminum alloy, with an aluminum content exceeding 99.5%, has good conductivity, but is slightly inferior to copper. |

| Price Cost | Copper is relatively expensive, leading to higher costs for copper busbars. | Aluminum is abundant and relatively inexpensive, making 1070 aluminum busbars more cost-effective. |

| Weight | Copper has a higher density and is heavier for the same volume. | Aluminum has about one-third of the density of copper, making 1070 aluminum busbars significantly lighter for the same volume, which helps reduce structural weight. |

| Strength | Copper busbars have higher mechanical strength, exhibiting greater tensile strength and durability. | 1070 aluminum busbars have lower mechanical strength and are weaker in tensile strength and durability compared to copper busbars. |

Sizes of HC aluminum electrical aluminum busbar

| Square angle aluminum bar | ||||||||||

| 2mm | 2*30 | 2*40 | 2*67 | 2*70 | 2.5* 25 | |||||

| 3mm | 3*10 | 3*15 | 3*20 | 3*25 | 3*30 | 3*40 | 3*50 | 3*60 | 3*67 | 3*75 |

| 3*110 | ||||||||||

| 4mm | 4*10 | 4*15 | 4*20 | 4*25 | 4*30 | 4*40 | 4*45 | 4*50 | 4*60 | 4.6*60 |

| 4.8*9.8 | ||||||||||

| 5mm | 5*15 | 5*20 | 5*25 | 5*30 | 5*35 | 5*40 | 5*50 | 5*60 | 5*80 | 5*100 |

| 6mm | 6*20 | 6*25 | 6*30 | 6*40 | 6*50 | 6*54 | 6*55 | 6*60 | 6*65 | 6*70 |

| 6*75 | 6*80 | 6*100 | 6*120 | 6*150 | 6*160 | |||||

| 6.3mm | 6.3*50 | 6.3*63 | 6.3*63.5 | 6.3*80 | 6.35*50.8 | 6.35*76.2 | ||||

| 7mm | 7.6*80 | 7*150 | 7*4*20*4 | |||||||

| 8mm | 8*11 | 8*30 | 8*40 | 8*50 | 8*51 | 8*60 | 8*63 | 8*63.5 | 8*65 | 8*70 |

| 8*80 | 8*90 | 8*100 | 8*120 | 8*125 | 8.8*28.6 | |||||

| 9mm | 9*170 | 9*125 | 9. 2*64 | |||||||

| 10mm | 10*20 | 10*25 | 10*30 | 10*40 | 10*45 | 10*50 | 10*60 | 10*63 | 10*65 | 10*70 |

| 10*80 | 10*90 | 10*100 | 10*110 | 10*114 | 10*120 | 10*125 | 10*140 | 10*150 | 10*160 | |

| 12mm | 12*30 | 12*40 | 12*45 | 12*50 | 12*60 | 12*70 | 12*76 | 12*80 | 12*100 | 12*120 |

| 12*125 | 12*130 | 12*140 | 12*150 | 12*160 | ||||||

| 12.5mm | 12.5*90 | 12.5*100 | 12.5*125 | 12.5*127 | 12.7*101.6 | 12.7*160 | ||||

| 13mm | 13*125 | 13*130 | 13*160 | |||||||

| 14mm | 14*100 | 14*120 | 14.5*80 | |||||||

| 15mm | 15*30 | 15*35 | 15*50 | 15*60 | 15*80 | 15*100 | 15*120 | 15*125 | 15*150 | |

| 16mm | 16*30 | 16*90 | 16*100 | 16*110 | 16*125 | 16*130 | 16*140 | 16*150 | 16*160 | |

| 20mm | 20*76 | 20*100 | 20*120 | 20*130 | ||||||

| Square bar | 19*19 | 30*45 | 15*15 | |||||||

| Round bar | Φ6 | Φ8 | Φ10 | Φ11 | Φ12 | Φ14 | Φ15 | Φ15.6 | Φ16 | Φ18 |

| Φ20 | Φ21 | Φ22 | Φ23 | Φ25 | Φ27 | Φ28 | Φ30 | Φ32 | Φ35 | |

| Φ38 | Φ40 | Φ45 | Φ50 | Φ55 | Φ60 | |||||

| Round angle aluminum bar | |||||||||

| 2mm | R2*20 | R2.5* 50 | |||||||

| 3mm | R3*30 | R3*40 | R3*50 | R3*60 | R3*80 | R3*100 | R3*120 | R3*160 | |

| 4mm | R4*25 | R4*30 | R4*35 | R4*40 | R4*50 | R4*60 | R4.1*44.1 | R4.7*151 | |

| 5mm | R5*30 | R5*35 | R5*40 | R5*45 | R5*50 | R5*60 | R5*70 | R5*75 | R5*80 |

| R5*90 | R5*100 | R5*120 | |||||||

| 6mm | R6*40 | R6*50 | R6*60 | R6*70 | R6*80 | R6*100 | R6*120 | R6*140 | R6*160 |

| R6.3*63 | R6.35*76.5 | ||||||||

| 7mm | R7*70 | ||||||||

| 8mm | R8*40 | R8*50 | R8*60 | R8*80 | R8*100 | RS*120 | |||

| 10mm | R10*20 | R10*40 | R10*50 | R10*60 | R10*75 | R10*80 | R10*100 | R10*120 | R10*125 |

| R10*150 | R10*160 | R10*170 | R10.4*25 | ||||||

| 12mm | R12*80 | R12*100 | R12*110 | R12*120 | R12*125 | R12*150 | R12*160 | ||

| 12.5mm | R12.5*80 | R12.5*125 | R12.7*90 | R12.7*127 | |||||

| 13mm | R13*120 | R13*125 | |||||||

| 14mm | R14*100 | R14*120 | R14*150 | ||||||

| 15mm | R15*100 | R15*120 | R15*130 | R15*150 | |||||

| 16mm | R16*150 | R16*160 | |||||||

| 19mm | R19.05*101.6 | R19.05*127 | |||||||

| 20mm | R20*80 | R20*120 | R20*130 | ||||||

| Special-shaped hypotenuse | *4*50 | *5*50 | *5*60 | *6*40 | *6*50 | *6*60 | *6*80 | *8*60 | *8*80 |

| *8*100 | *8*120 | *10*40 | *10*80 | *10*100 | *10*120 | *12*80 | *12*100 | *12*120 | |

| *15*120 | *20*130 | *28*60 | |||||||

Aluminum Busbar Selection Suggestions

- Current-carrying capacity calculation: Refer to IEC 60439, considering the ambient temperature (for example, at 40°C, the current-carrying capacity of a 100×10mm² 1070 busbar is approximately 1550A).

- Alternatives: If higher strength is required, you can choose 6063-T6 aluminum alloy (with 50% IACS conductivity and a tensile strength of 215 MPa), but the cost will increase by 20%.

The 1070 aluminum busbar, with its high conductivity, lightweight, and cost advantages, is the preferred choice for medium and low-voltage distribution systems, especially suitable for fixed installations and light to medium load scenarios.

Quality Issues to Pay Attention to When Purchasing

The 1070 aluminum busbar is an ideal solution for modern electrical applications, where performance, lightweight design, and cost-effectiveness are critical. Its high purity (≥99.7%), excellent conductivity, and adaptable manufacturing processes make it the preferred choice for distribution systems, transformer structures, and various industrial and commercial applications.