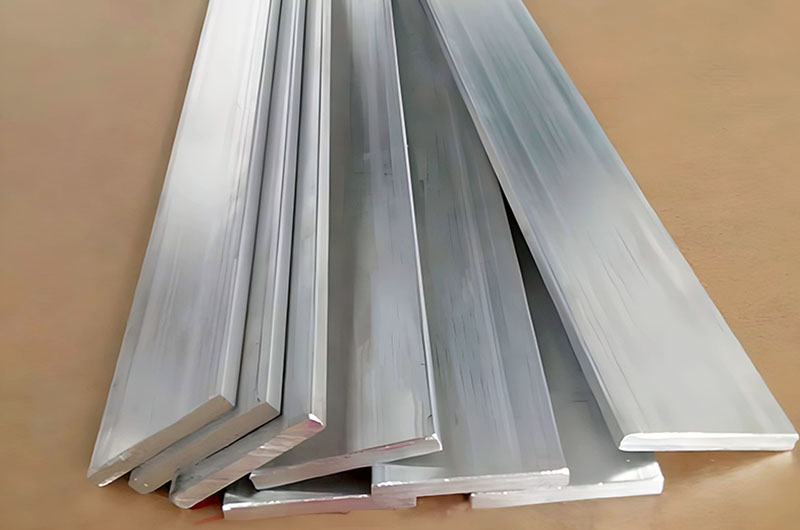

1060 aluminum busbar is a flat metal conductor designed to efficiently distribute power within systems such as distribution panels, substations, and industrial equipment. It is made of 99.6% pure aluminum (alloy 1060), balancing cost, conductivity, and weight, making it a popular choice for electrical applications.

HC Aluminum 1060 electrical aluminum busbar specification

| Attribute | Details |

| Model Number | 1060 |

| Material | Aluminum |

| Surface Treatment | Zinc, Nickel, Tin, Silver, etc. |

| Tolerance | +/- 0.1mm |

| Length | Up to 6m |

| Width | 10mm - 200mm |

| Thickness | 0.15mm - 40mm |

| Application | Electric |

| Processing | Stamping, Bending, Drilling, Threading, Polishing, etc. |

1060 Aluminum Busbar Dimensions and Tolerances

| Parameter | Typical Range | Tolerance (Standard) |

| Thickness | 1.5 mm – 25 mm | ±0.1 mm – ±0.5 mm |

| Width | 10 mm – 300 mm | ±0.5 mm – ±1 mm |

| Length | Custom Cut-to-Length | ±10 mm |

| Flatness | Standard per ASTM B209 | Varies by manufacturer |

| Edge Straightness | Standard per ASTM B209 | Varies by manufacturer |

1060 aluminum busbar Composition and Material Properties

- High Purity: The "1060" designation refers to an aluminum alloy with approximately 99.6% aluminum content. This high purity enables excellent electrical conductivity, which is crucial for minimizing energy loss in busbar applications.

- Density: 2.7 g/cm³ (lightweight, about 30% of the weight of copper).

- Electrical Conductivity: Due to its high purity, 1060 aluminum has excellent electrical conductivity, making it an effective choice for busbars that must carry high currents. Although its conductivity is lower than copper, its lower cost and lighter weight often justify its use in many industrial and commercial applications.

- Mechanical Properties: While 1060 aluminum is softer and more ductile than stronger alloys (such as those in the 6000 series), it provides sufficient mechanical strength for many busbar applications where high mechanical stress is not a primary concern. Its excellent formability means it can be extruded or shaped into various cross-sectional profiles.

- Corrosion Resistance: Its inherent corrosion resistance makes 1060 aluminum suitable for harsh environments and outdoor applications where long-term durability is important.

1060 Aluminum Busbar Electrical and Thermal Conductivity

- Electrical Conductivity: 61% IACS (very good for a non-copper conductor).

- Thermal Conductivity: 234 W/m·K, which aids in heat dissipation.

- Current Carrying Capacity: Lower than copper, but sufficient for many applications; size adjustments can compensate for its lower conductivity.

1060 Aluminum Busbar Mechanical Properties

- Elongation: Easy to form but requires structural support in high-stress applications.

- Hardness: Low, requiring careful handling to avoid deformation.

| Ultimate Tensile Strength (kgf/mm2) | Ultimate Shearing Strength (kgf/mm2) | Elastic Modulus (kgf/mm2) | 0.2% Tensile-proof Strength (kgf/mm2) |

| 20.5/25 | 15 | 6, 700 | 16.5/22 |

1060 aluminum busbar Corrosion Resistance

1060 aluminum busbar, with its naturally formed oxide layer, exhibits good corrosion resistance in most neutral or mildly corrosive environments, making it suitable for indoor and most outdoor applications. However, in highly acidic, highly alkaline, or marine salt spray environments, additional surface protection measures should be taken to ensure long-term reliable operation.

- Oxide Layer: Naturally formed protective layer that resists moisture and chemicals.

- Environmental Suitability: Suitable for indoor/outdoor use; avoid use in highly alkaline/acidic environments without coating.

1060 aluminum busbar Typical Applications and Corrosion Resistance Requirements

| Application Field | Corrosion Resistance Requirements | Recommended Protective Measures |

| Power Distribution Systems | Requires resistance to moisture corrosion | Natural oxide layer or anodizing |

| Rail Transit | Adaptability to outdoor environments | Anodizing or anti-oxidation coating |

| Marine Environment | Requires protection against salt spray corrosion | Special coating (e.g., fluorocarbon paint) |

| Chemical Plants | Requires resistance to acid and alkali corrosion | Insulation coating or special oxidation treatment |

1060 aluminum busbar Manufacturing and Shape Factors

- Extrusion and Manufacturing: Busbars are typically produced through an extrusion process where 1060 aluminum is forced through a die to form a continuous profile. This method allows manufacturers to customize cross-sectional areas and shapes (e.g., flat, rectangular, or custom geometries) based on specific electrical load and installation requirements.

- Surface Treatment: Depending on the application, these busbars can be treated or anodized to further enhance corrosion resistance and surface durability.

- Customization: Many suppliers offer 1060 aluminum busbars in various sizes and lengths, allowing engineers to select sizes that match their system's current-carrying capacity and installation constraints.

1060 aluminum busbar Applications

| Application Field | Description |

| Power Distribution | 1060 aluminum busbars are used in switchgear, distribution panels, and substations as low-resistance current paths to ensure efficient energy transfer. Due to their high conductivity and excellent thermal performance, these busbars reduce power loss and improve the overall efficiency of power systems. Additionally, the good machinability of 1060 aluminum allows for easy adaptation to different installation needs, making it widely used in power grids and industrial power supply systems. |

| Renewable Energy Systems | 1060 aluminum busbars are commonly used in solar photovoltaic installations and wind turbines as lightweight and corrosion-resistant conductors to ensure long-term stable power transmission. In solar systems, they connect solar panels, inverters, and combiner boxes, providing an efficient energy transfer path. In wind power systems, 1060 aluminum busbars are used for electrical connections between the tower and converters, ensuring low-loss transmission during wind energy conversion. |

| Industrial Machinery | 1060 aluminum busbars play a critical role in control panels and heavy equipment, ensuring efficient and reliable current distribution. Due to their good conductivity and corrosion resistance, these busbars can stably carry high currents and are suitable for long-term operation in industrial environments. Additionally, the flexibility and machinability of 1060 aluminum busbars allow them to be customized based on equipment requirements, optimizing circuit layouts and enhancing the efficiency and safety of industrial machinery. |

Advantages of 1060 aluminum busbar Over Alternatives

- Cost-Effectiveness: Aluminum is generally cheaper than copper, and 1060 aluminum achieves a good balance between conductivity and cost.

- Lightweight: 70% lighter than copper, reducing weight and simplifying handling and installation.

- High Conductivity: Although its absolute conductivity is lower than copper, its high purity ensures low resistance when properly sized.

1060 aluminum busbar Standards and Compliance

- ASTM B317: Regulates extruded aluminum busbars.

- IEC 60439: Ensures compatibility with low-voltage switchgear.

Common sizes of HC Aluminum electrical aluminum busbar

| Square angle aluminum bar | ||||||||||

| 2mm | 2*30 | 2*40 | 2*67 | 2*70 | 2.5* 25 | |||||

| 3mm | 3*10 | 3*15 | 3*20 | 3*25 | 3*30 | 3*40 | 3*50 | 3*60 | 3*67 | 3*75 |

| 3*110 | ||||||||||

| 4mm | 4*10 | 4*15 | 4*20 | 4*25 | 4*30 | 4*40 | 4*45 | 4*50 | 4*60 | 4.6*60 |

| 4.8*9.8 | ||||||||||

| 5mm | 5*15 | 5*20 | 5*25 | 5*30 | 5*35 | 5*40 | 5*50 | 5*60 | 5*80 | 5*100 |

| 6mm | 6*20 | 6*25 | 6*30 | 6*40 | 6*50 | 6*54 | 6*55 | 6*60 | 6*65 | 6*70 |

| 6*75 | 6*80 | 6*100 | 6*120 | 6*150 | 6*160 | |||||

| 6.3mm | 6.3*50 | 6.3*63 | 6.3*63.5 | 6.3*80 | 6.35*50.8 | 6.35*76.2 | ||||

| 7mm | 7.6*80 | 7*150 | 7*4*20*4 | |||||||

| 8mm | 8*11 | 8*30 | 8*40 | 8*50 | 8*51 | 8*60 | 8*63 | 8*63.5 | 8*65 | 8*70 |

| 8*80 | 8*90 | 8*100 | 8*120 | 8*125 | 8.8*28.6 | |||||

| 9mm | 9*170 | 9*125 | 9. 2*64 | |||||||

| 10mm | 10*20 | 10*25 | 10*30 | 10*40 | 10*45 | 10*50 | 10*60 | 10*63 | 10*65 | 10*70 |

| 10*80 | 10*90 | 10*100 | 10*110 | 10*114 | 10*120 | 10*125 | 10*140 | 10*150 | 10*160 | |

| 12mm | 12*30 | 12*40 | 12*45 | 12*50 | 12*60 | 12*70 | 12*76 | 12*80 | 12*100 | 12*120 |

| 12*125 | 12*130 | 12*140 | 12*150 | 12*160 | ||||||

| 12.5mm | 12.5*90 | 12.5*100 | 12.5*125 | 12.5*127 | 12.7*101.6 | 12.7*160 | ||||

| 13mm | 13*125 | 13*130 | 13*160 | |||||||

| 14mm | 14*100 | 14*120 | 14.5*80 | |||||||

| 15mm | 15*30 | 15*35 | 15*50 | 15*60 | 15*80 | 15*100 | 15*120 | 15*125 | 15*150 | |

| 16mm | 16*30 | 16*90 | 16*100 | 16*110 | 16*125 | 16*130 | 16*140 | 16*150 | 16*160 | |

| 20mm | 20*76 | 20*100 | 20*120 | 20*130 | ||||||

| Square bar | 19*19 | 30*45 | 15*15 | |||||||

| Round bar | Φ6 | Φ8 | Φ10 | Φ11 | Φ12 | Φ14 | Φ15 | Φ15.6 | Φ16 | Φ18 |

| Φ20 | Φ21 | Φ22 | Φ23 | Φ25 | Φ27 | Φ28 | Φ30 | Φ32 | Φ35 | |

| Φ38 | Φ40 | Φ45 | Φ50 | Φ55 | Φ60 | |||||

| Round angle aluminum bar | |||||||||

| 2mm | R2*20 | R2.5* 50 | |||||||

| 3mm | R3*30 | R3*40 | R3*50 | R3*60 | R3*80 | R3*100 | R3*120 | R3*160 | |

| 4mm | R4*25 | R4*30 | R4*35 | R4*40 | R4*50 | R4*60 | R4.1*44.1 | R4.7*151 | |

| 5mm | R5*30 | R5*35 | R5*40 | R5*45 | R5*50 | R5*60 | R5*70 | R5*75 | R5*80 |

| R5*90 | R5*100 | R5*120 | |||||||

| 6mm | R6*40 | R6*50 | R6*60 | R6*70 | R6*80 | R6*100 | R6*120 | R6*140 | R6*160 |

| R6.3*63 | R6.35*76.5 | ||||||||

| 7mm | R7*70 | ||||||||

| 8mm | R8*40 | R8*50 | R8*60 | R8*80 | R8*100 | RS*120 | |||

| 10mm | R10*20 | R10*40 | R10*50 | R10*60 | R10*75 | R10*80 | R10*100 | R10*120 | R10*125 |

| R10*150 | R10*160 | R10*170 | R10.4*25 | ||||||

| 12mm | R12*80 | R12*100 | R12*110 | R12*120 | R12*125 | R12*150 | R12*160 | ||

| 12.5mm | R12.5*80 | R12.5*125 | R12.7*90 | R12.7*127 | |||||

| 13mm | R13*120 | R13*125 | |||||||

| 14mm | R14*100 | R14*120 | R14*150 | ||||||

| 15mm | R15*100 | R15*120 | R15*130 | R15*150 | |||||

| 16mm | R16*150 | R16*160 | |||||||

| 19mm | R19.05*101.6 | R19.05*127 | |||||||

| 20mm | R20*80 | R20*120 | R20*130 | ||||||

| Special-shaped hypotenuse | *4*50 | *5*50 | *5*60 | *6*40 | *6*50 | *6*60 | *6*80 | *8*60 | *8*80 |

| *8*100 | *8*120 | *10*40 | *10*80 | *10*100 | *10*120 | *12*80 | *12*100 | *12*120 | |

| *15*120 | *20*130 | *28*60 | |||||||

Limitations and Considerations

Strength: Lower mechanical strength compared to alloys like 6061; may require thicker profiles.

Electrochemical Corrosion: Use compatible connectors (such as aluminum or insulated fittings) when in contact with different metals.

Mechanical Strength: While suitable for many applications, the relatively soft nature of 1060 aluminum means it may not be suitable for areas with expected high mechanical loads.

Thermal Expansion: The thermal expansion coefficient of aluminum busbars is higher than that of copper. This should be considered in design, especially in environments with significant temperature variations.

Manufacturing and Installation

- Machinability: Easy to cut, bend, or drill.

- Welding: Compatible with TIG/MIG methods.

- Installation Tips: Apply anti-oxidation compounds on joints; tighten connections to specifications to prevent loosening.

The 1060 aluminum busbar is a robust and efficient conductor, well-suited for power distribution in various applications. Its high purity ensures excellent conductivity and corrosion resistance while being easy to manufacture, offering a wide range of design options. Engineers must weigh the advantages of low cost and weight against the specific mechanical and thermal requirements of the installation.

The 1060 aluminum busbar is a cost-effective, lightweight power distribution solution with excellent conductivity and corrosion resistance. While not as strong as some alloys, its advantages in weight, cost, and sustainability make it an ideal choice for applications where mechanical stress is secondary to efficient power transmission. Proper design and installation ensure reliable performance across industries.