HC Aluminum Busbar

What Is an Aluminum Busbar?

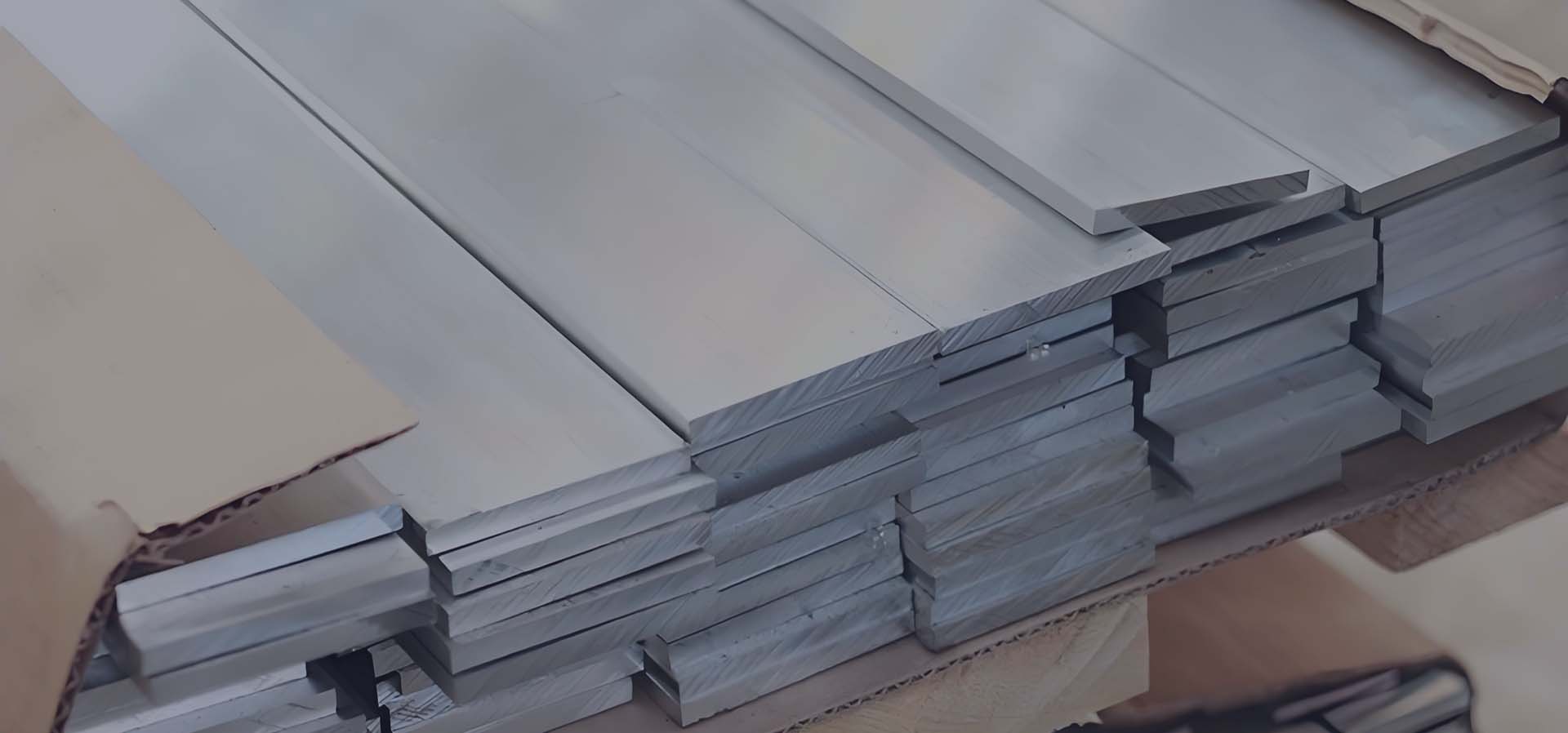

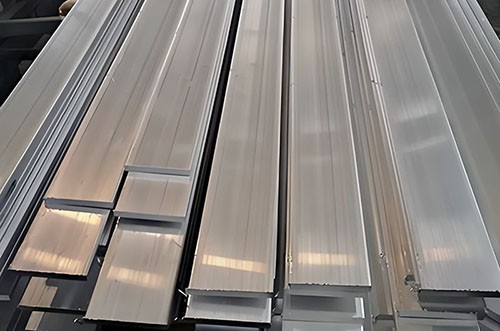

Aluminum busbars are high-section conductors used for power transmission and distribution, widely applied in power systems, industrial equipment, and new energy fields. They serve as the central connection points in distribution systems (located in switchgear, distribution panels, and substations), helping to guide large currents with minimal energy loss.

The core function of aluminum busbars is to replace traditional cables and serve as the main conductive body in low-voltage and medium-voltage systems, connecting transformers, switch cabinets, distribution boxes, and other equipment.

Aluminum busbars (Aluminum Busbar) are made of high-purity aluminum or aluminum alloys and are efficient conductors used for transmitting and distributing electrical energy in power systems. They are typically made from high-purity aluminum (such as 1060, 1070, or 6063 aluminum alloys). Their design is intended to carry large currents and is used to collect and distribute electrical currents.

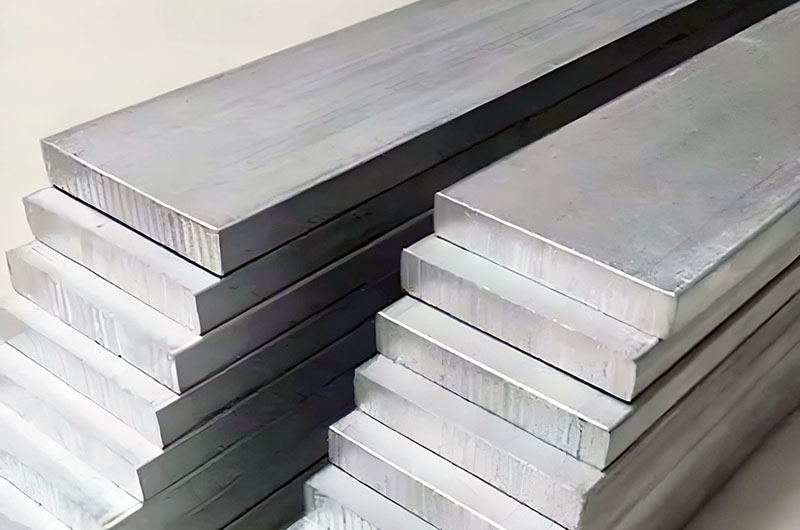

- Typical cross-sections: rectangular (such as 30×5mm, 50×6mm, 100×10mm, etc.), with an increased cross-sectional area to improve current carrying capacity.

- Surface treatments: tin-plated (for oxidation prevention), anodized (for enhanced corrosion resistance), coated with insulating paint (for safety protection).

HC Aluminum offers a comprehensive range of electrical busbar products, including aluminum busbars, copper busbars, and copper-clad aluminum busbars. Popular aluminum busbar products include 6101, 1050, 1060, 1070, 1100, 1350, 6061, 6063, 6082... They are widely used as electrical conductors in distribution systems.

HC Aluminum EC-grade aluminum busbars comply with ASTM B317, ASTM B236, IEC 60105, ISO 209-1,2, DIN EN 755-2, EN 573-3, and other standards, and are widely used as electrical conductors in distribution systems.

We provide aluminum materials in various shapes and sizes, including rectangular, round, and flat bars.

Aluminum Busbar Material Properties

Aluminum busbars use high-purity aluminum (such as 1050, 1060) or aluminum alloys (such as 6063, 6061), with electrical conductivity typically ranging from 55% to 62% IACS (International Annealed Copper Standard), offering both good conductivity and mechanical strength.

- Electrical conductivity: The conductivity is about 35-61% IACS (depending on the purity of the aluminum and the alloy type). For example, 1060 pure aluminum has a conductivity of about 61%. However, its density is only 30% of copper, making it lighter.

- Current-carrying capacity: The larger the cross-section, the higher the current-carrying capacity (for example, a 100×10mm² aluminum busbar can carry about 1400A in a 40℃ environment).

- Lightweight: With a density of 2.7g/cm³, it is only 30% of the density of copper busbars, reducing the cost of supporting structures.

- Corrosion resistance: Aluminum forms a dense oxide film (Al₂O₃) in the air, but surface treatments (such as tin-plating, painting, or anodizing) are required in humid or polluted environments to enhance protection.

- Mechanical properties: Aluminum has lower tensile strength, so aluminum alloys (such as 6063) are used to improve strength. However, its ductility should be considered when bending.

- Thermal performance: Aluminum's ability to dissipate heat is a key advantage in power systems. However, since aluminum's electrical conductivity is lower than that of copper, aluminum busbars typically need a larger surface area to manage the heat generated by high currents. Additionally, the higher thermal expansion rate of aluminum must be considered in the design to ensure stable mechanical connections.

The common grades of aluminum for electrical busbars

| Aluminum Alloy | Image | Description |

| 1060 aluminum busbar |

|

1060 aluminum alloy has excellent corrosion resistance and high electrical conductivity, widely used in electrical busbars. It is typically formed by extrusion or rolling, with excellent workability. However, the disadvantage of 1060 aluminum alloy is its relatively low strength, limiting its use in high-stress applications. |

| 1100 aluminum busbar |

|

1100 aluminum alloy has at least 99.0% aluminum content and is the highest-strength material in the 1000 series. In its fully softened and annealed state, it exhibits excellent formability. Additionally, 1100 aluminum alloy has good thermal conductivity, making it commonly used in heat exchangers and radiators. The disadvantage of 1100 aluminum alloy is that its strength is still relatively low compared to high-strength alloys. |

| 1350 aluminum busbar |

|

1350 aluminum alloy is mainly used in battery busbar materials, with at least 99.5% aluminum content, offering extremely high electrical and thermal conductivity. It exhibits excellent corrosion resistance and strict impurity control that may affect conductivity. However, the drawback of 1350 aluminum alloy is its low mechanical strength, and it cannot be strengthened by heat treatment, limiting its use in certain high-strength applications. |

| 6063 aluminum busbar |

|

6063 aluminum alloy, with magnesium and silicon as the main alloying elements, provides good mechanical properties and weldability. The strength of 6063 aluminum alloy can be enhanced through heat treatment while maintaining good electrical conductivity. Additionally, 6063 aluminum alloy has excellent bending properties, making it widely used in electrical busbars and structural components. The disadvantage of 6063 aluminum alloy is its relatively lower strength compared to some high-strength aluminum alloys. |

| 6101 aluminum busbar |

|

6101 aluminum alloy contains magnesium and silicon, offering higher mechanical strength while maintaining good electrical conductivity. Its yield strength is higher than that of 1350, and it has better creep resistance at elevated temperatures. This makes 6101 aluminum alloy an ideal choice for electrical busbars requiring higher strength and durability. The drawback of 6101 aluminum alloy is that its electrical conductivity is slightly lower than that of 1350, but it is still suitable for high-performance electrical applications. |

Aluminum Busbar Technical Parameters

| Parameter | Description |

| Current Carrying Capacity | The current carrying capacity of aluminum busbars is closely related to the cross-sectional area, ambient temperature, and heat dissipation conditions. For example, an aluminum busbar with a cross-sectional area of 100×10 mm² can carry approximately 1200-1500A in an environment with a temperature of 40°C. |

| Resistivity | The resistivity of aluminum is about 2.82×10⁻⁸ Ω·m, which is approximately 1.6 times that of copper. Due to relatively poorer conductivity, the cross-sectional area needs to be increased to compensate and meet power transmission demands. |

| Temperature Rise | Aluminum busbars are usually required to maintain a temperature rise of no more than 50°C during operation, for example, rising from 30°C to 80°C. In cases of overload, proper heat dissipation design is needed to ensure system stability and safety. |

| Mechanical Strength | The tensile strength of aluminum alloy busbars can reach 150-300 MPa, which is higher than that of pure aluminum, making it suitable for high current and vibration environments, improving durability and stability. |

| Short Circuit Endurance | Aluminum busbars need to withstand short-circuit currents for several seconds, such as 30kA/3s. This imposes high requirements on their thermal stability and mechanical strength to prevent deformation or damage. |

Aluminum Busbar Size Chart

Here's a reference chart for aluminum busbar sizes and their corresponding ampacity ratings under typical conditions:

| Busbar Size (Width × Thickness, mm) | Cross-Sectional Area (mm²) | Approx. Ampacity (A) |

| 20 × 6 | 120 | 96 |

| 20 × 10 | 200 | 160 |

| 25 x 6 | 150 | 364 |

| 40 x 6 | 240 | 545 |

| 50 x 6 | 300 | 660 |

| 60 x 6 | 360 | 782 |

| 80 x 6 | 480 | 995 |

| 100 x 6 | 600 | 1215 |

| 125 x 6 | 750 | 1467 |

Aluminum Busbar Ampacity Chart

| Converting Copper to Aluminum using an Ampacity Chart | ||||||||||||

| Ampacity Conversion Chart | Copper C110 | 30° C Rise | 50° C Rise | 65° C Rise | Aluminum 6101 | 30° C Rise | 50° C Rise | 65° C Rise | ||||

| Flat Bar Size in Inches | Sq. In | Circ Mils Thousands | Weight Per Ft in Lb. | DC Resistance at 20° C, Microhms/Ft | 60 Hz Ampacity Amp* | Weight Per Ft in Lb. | DC Resistance at 20° C, Microhms/Ft | 60 Hz Ampacity Amp** | ||||

| 1/2*1 | 0.5 | 637 | 1.93 | 16.5 | 620 | 820 | 940 | 0.585 | 31 | 347 | 459 | 526 |

| 1/2*1 1/2 | 0.75 | 955 | 2.9 | 11 | 830 | 1100 | 1250 | 0.878 | 21 | 465 | 616 | 700 |

| 1/2*2 | 1 | 1270 | 3.86 | 8.23 | 1000 | 1350 | 1550 | 1.17 | 15 | 560 | 756 | 868 |

| 1/2*2 1/2 | 1.25 | 1590 | 4.83 | 6.58 | 1200 | 1600 | 1850 | 1.463 | 12 | 672 | 896 | 1036 |

| 1/2*3 | 1.5 | 1910 | 5.8 | 5.49 | 1400 | 1850 | 2150 | 1.755 | 10 | 784 | 1036 | 1204 |

| 1/2*3 1/2 | 1.75 | 2230 | 6.76 | 4.7 | 1550 | 2100 | 2400 | 2.048 | 9 | 868 | 1176 | 1344 |

| 1/2*4 | 2 | 2550 | 7.73 | 4.11 | 1700 | 2300 | 2650 | 2.34 | 8 | 952 | 1288 | 1484 |

| 1/2*5 | 2.5 | 3180 | 9.66 | 3.29 | 2050 | 2750 | 3150 | 2.925 | 6 | 1148 | 1540 | 1764 |

| 1/2*6 | 3 | 3820 | 11.6 | 2.74 | 2400 | 3150 | 3650 | 3.51 | 5 | 1344 | 1764 | 2044 |

| 1/2*8 | 4 | 5090 | 15.5 | 2.06 | 3000 | 4000 | 4600 | 4.68 | 4 | 1680 | 2240 | 2576 |

| 1/4*1/2 | 0.125 | 159 | 0.483 | 65.8 | 240 | 315 | 360 | 0.146 | 123 | 134 | 176 | 202 |

| 1/4*3/4 | 0.188 | 239 | 0.726 | 43.8 | 320 | 425 | 490 | 0.220 | 82 | 179 | 238 | 274 |

| 1/4*1 | 0.25 | 318 | 0.966 | 32.9 | 400 | 530 | 620 | 0.293 | 62 | 224 | 297 | 347 |

| 1/4*1 1/2 | 0.375 | 477 | 1.450 | 21.9 | 560 | 740 | 880 | 0.439 | 41 | 314 | 414 | 482 |

| 1/4*2 | 0.5 | 637 | 1.930 | 16.5 | 710 | 940 | 1100 | 0.585 | 31 | 398 | 526 | 616 |

| 1/4*2 1/2 | 0.625 | 796 | 2.410 | 13.2 | 850 | 1150 | 1300 | 0.731 | 25 | 476 | 644 | 728 |

| 1/4*3 | 0.75 | 955 | 2.900 | 11 | 990 | 1300 | 1550 | 0.878 | 21 | 554 | 728 | 868 |

| 1/4*3 1/2 | 0.875 | 1110 | 3.380 | 9.4 | 1150 | 1500 | 1750 | 1.024 | 18 | 644 | 840 | 980 |

| 1/4*4 | 1 | 1270 | 3.860 | 8.23 | 1250 | 1700 | 1950 | 1.170 | 15 | 700 | 952 | 1092 |

| 1/4*5 | 1.25 | 1590 | 4.830 | 6.58 | 1500 | 2000 | 2350 | 1.463 | 12 | 840 | 1120 | 1316 |

| 1/4*6 | 1.5 | 1910 | 5.800 | 5.49 | 1750 | 2350 | 2700 | 1.755 | 10 | 980 | 1316 | 1512 |

| 1/8*1/2 | 0.0625 | 79.6 | 0.241 | 132 | 153 | 205 | 235 | 0.073 | 247 | 86 | 115 | 132 |

| 1/8*3/4 | 0.0938 | 119 | 0.362 | 87.7 | 215 | 285 | 325 | 0.110 | 164 | 120 | 160 | 182 |

| 1/8*1 | 0.125 | 159 | 0.483 | 65.8 | 270 | 360 | 415 | 0.146 | 123 | 151 | 202 | 232 |

| 1/8*1 1/2 | 0.188 | 239 | 0.726 | 43.8 | 385 | 510 | 590 | 0.220 | 82 | 216 | 286 | 330 |

| 1/8*2 | 0.25 | 318 | 0.966 | 32.9 | 495 | 660 | 760 | 0.293 | 62 | 277 | 370 | 426 |

| 1/8*2 1/2 | 0.312 | 397 | 1.210 | 26.4 | 600 | 800 | 920 | 0.365 | 49 | 336 | 448 | 515 |

| 1/8*3 | 0.375 | 477 | 1.450 | 21.9 | 710 | 940 | 1100 | 0.439 | 41 | 398 | 526 | 616 |

| 1/8*3 1/2 | 0.438 | 558 | 1.690 | 18.8 | 810 | 1100 | 1250 | 0.512 | 35 | 454 | 616 | 700 |

| 1/8*4 | 0.5 | 636 | 1.930 | 16.5 | 900 | 1200 | 1400 | 0.585 | 31 | 504 | 672 | 784 |

| 1/16*1/2 | 0.0312 | 39.7 | 0.121 | 264 | 103 | 136 | 157 | 0.037 | 494 | 58 | 76 | 88 |

| 1/16*3/4 | 0.0469 | 59.7 | 0.181 | 175 | 145 | 193 | 225 | 0.055 | 327 | 81 | 108 | 126 |

| 1/16*1 | 0.0625 | 79.6 | 0.242 | 132 | 187 | 250 | 285 | 0.073 | 247 | 105 | 140 | 160 |

| 1/16*1 1/2 | 0.0938 | 119 | 0.362 | 87.7 | 270 | 355 | 410 | 0.110 | 164 | 151 | 199 | 230 |

| 1/16*2 | 0.125 | 159 | 0.483 | 65.8 | 345 | 460 | 530 | 0.146 | 123 | 193 | 258 | 297 |

| Source: Copper Development Organization; Aluminum Association | ||||||||||||

| Note: Ratings depend upon configuration, air flow, ambient temp, etc. The values depicted are an approximation. Controlled testing is always required to validate. | ||||||||||||

| Other considerations Forming the busbar (aluminum has a tendency to crack with very tight radius) Electroplating the busbar (white rust on aluminum, oxidation is an issue with aluminum) Configuration of the busbar (vertical or horizontal configuration) | ||||||||||||

Aluminum Busbar Plating

| Plating Type | Process | Standards | Advantages / Considerations |

| Electrolytic Tin Plating Aluminum Busbar | After zincate, plated in acid tin bath under electric current | ASTM B545 | Excellent corrosion resistance, prevents aluminum oxide, very solderable, cost-effective |

| Immersion (Non Electrolytic) Silver Plating Aluminum Busbar | Silver deposited via chemical replacement reaction, no external current | N/A | High conductivity, prone to tarnish—requires inhibitors or top-coats |

| Electrolytic Silver Plating Aluminum Busbar | Electroplated after zincate with controlled current density | ASTM B700 | Low resistivity, durable coating, suitable for high-current applications |

| Electroless Nickel Plating Aluminum Busbar | Uniform nickel-phosphorus layer deposited chemically after zincate | ASTM B733 | Excellent corrosion and wear resistance, good solder barrier, uniform thickness on complex shapes |

Common Types of Aluminum Busbars

Shape Classification:

| Type | Features and Applications |

| Rectangular Aluminum Busbar | The most common type of aluminum busbar, with a large surface area that aids in heat dissipation, suitable for high current applications. It has a low cost, is easy to process, and is commonly used in medium and low voltage distribution cabinets, such as the 80×10 mm² cross-section. |

| Trench-type Busbar | Featuring U-shaped or C-shaped cross-sections, it increases the heat dissipation area and improves current-carrying capacity, suitable for high current applications of up to several thousand amperes. |

| Tubular Aluminum Busbar | Uses a hollow round tube or square tube structure, with a low skin effect, making it suitable for high-frequency or ultra-high voltage power transmission, such as transmission lines of 110kV and above. |

| Flexible Busbar | Made of multiple strands of aluminum wire or braided bands, it has good flexibility and is suitable for applications requiring flexible connections, such as transformer bushings. |

| Round Aluminum Busbar | Suitable for high-frequency applications or those requiring uniform current distribution, ensuring even current flow and reducing local overheating issues. |

Insulation Types:

- Bare Busbar: Exposed directly, requiring safe spacing, commonly used in enclosed cabinets.

- Insulated Busbar: Coated with epoxy resin, heat-shrinkable tubing, or silicone rubber to enhance safety.

Aluminum Busbar Surface Treatment

| Surface Treatment Method | Description |

| Anodizing | Anodized aluminum busbars undergo an electrochemical reaction to form a dense layer of aluminum oxide on the surface. This layer significantly enhances the corrosion resistance of the busbar, extending its service life in humid or corrosive environments. Additionally, the oxide layer provides some electrical insulation, reducing the contact resistance increase caused by surface oxidation. |

| Tin/Silver Plating | Aluminum busbars with tin or silver plating have a conductive metal coating on the surface, improving the conductivity of the contact area and reducing resistance increase due to oxidation during long-term use. Silver-plated busbars, due to the superior conductivity of silver, are typically used in high-end power equipment that requires extremely low contact resistance, while tin-plated busbars are more commonly used in standard power applications due to their lower cost. |

| Insulation Coating | Aluminum busbars with an insulation coating are typically coated with epoxy resin or other high-performance electrical insulation materials to prevent short circuits or electrical arcing. This is especially suitable for compact distribution systems or environments requiring additional electrical protection. Additionally, the insulation coating provides some moisture and corrosion resistance, prolonging the service life of the busbar. |

Aluminum Busbar Construction and Design Considerations

Material and Alloy Selection:

Common alloys such as 6061, 6063, or 6101 are selected due to their balance of conductivity, mechanical strength, and ease of manufacturing. The choice of alloy depends on the load requirements of the application, environmental conditions, and thermal performance needs.

Size and Cross-section:

Since aluminum has lower conductivity than copper, the busbar’s width or thickness is often increased to ensure equivalent current-carrying capacity. For example, increasing the width of an aluminum busbar by approximately 27% or the thickness by about 50% can achieve similar thermal performance to a copper busbar.

Insulation and Finishing:

Depending on the application, aluminum busbars can be used in insulated configurations (to enhance safety) or non-insulated configurations (for high current systems). Dielectric coatings, such as epoxy powder coatings, help prevent environmental degradation and ensure long-term performance.

Mechanical Connections:

Due to aluminum's inherent thermal expansion and surface irregularities, particular attention must be paid to mechanical fasteners. Proper torque settings and the use of connection washers or other fittings can prevent loosening over time.

Aluminum Busbar Applications

- Power Generation and Transmission: Connecting generators, transformers, switchgear, and transmitting current at the kiloampere level.

- Industrial Equipment: Main conductors for high-current equipment such as aluminum electrolysis plants and electric furnaces. For example, aluminum electrolysis cells that withstand high current and high-temperature corrosive environments.

- Rail Transit: DC busbars for metro/high-speed rail traction substations.

- Renewable Energy Systems: Low-loss connections between strings of batteries in photovoltaic power stations and energy storage systems.

- Building Distribution: High-density busbar trunking in data centers and commercial buildings, as an alternative to traditional cables.

- Power Substations: Connecting transformers to switchgear, replacing cable bundles.

- Photovoltaic Inverters and Energy Storage Systems: DC busbars carrying high currents, with lightweight construction reducing the load on the mounting frame.

- Data Centers: Reducing space occupation in dense power distribution and improving heat dissipation efficiency.

Aluminum Busbar Advantages and Limitations

Advantages of Aluminum Busbars:

- Cost-effectiveness: Costs only 30%-50% of copper busbars, making it suitable for large cross-sectional requirements.

- Lightweight: At the same current-carrying capacity, it is 50% lighter than copper, simplifying support structures.

- Good Heat Dissipation: With a large surface area, natural cooling efficiency is high.

- Low Cost: Aluminum costs only one-third of copper, suitable for large cross-sectional requirements.

- Good Fatigue Resistance and Oxidation Resistance (aluminum alloys).

- Easy to Process: Aluminum has good ductility and can be bent into complex shapes. It can be cut, drilled, and bent to fit different cabinet layouts.

- Environmentally Friendly: Aluminum has a high recycling rate of 95%, and its carbon emissions are 90% lower than copper, meeting sustainability requirements.

Disadvantages of Aluminum Busbars:

- Joint Oxidation: Conductive paste must be applied, or copper-aluminum transition joints must be used.

- Thermal Expansion: Aluminum has a high linear expansion coefficient (23×10⁻⁶/°C), so long busbars need expansion joints.

- Insufficient Strength: Large spans require additional support points or the use of steel-core aluminum busbars. Long spans need additional support points, or aluminum alloys (such as 6063-T5) should be used.

- Lower Conductivity than Copper: Larger cross-sectional areas are required for the same current-carrying capacity.

- Aluminum’s Creep Characteristics May Lead to Loosening at Connections: Regular maintenance is required.

- High Welding Process Requirements: Requires TIG welding or laser welding.

Aluminum Busbar Manufacturing and Installation Points

Aluminum Busbar Manufacturing Process: Extrusion (profiled busbars), Rolling (thin sheets), Stranding (soft busbars).

Aluminum Busbar Production Process Flow:

| Production Process Flow | Description |

| Casting | The production of aluminum busbars begins with the casting process, where aluminum ingots are heated and melted, with alloying elements (such as magnesium and silicon) added to improve mechanical properties and conductivity. The molten metal is then cast into billets of specific dimensions, providing raw material for further processing. |

| Extrusion | In the extrusion process, the aluminum billets are heated to the appropriate temperature and then forced through a mold under high pressure to form the desired busbar cross-section. The extrusion process can produce aluminum busbars in various shapes, such as rectangular, channel, or tubular, to meet different application needs. |

| Cold Working | After extrusion, the busbars may undergo further cold working, such as drawing or rolling, to improve surface finish, enhance mechanical properties, and further control dimensional precision. This step helps improve the final quality of the product. |

| Cutting and Drilling | According to customer requirements, the busbars are cut to specific lengths, and drilling is performed to facilitate subsequent installation and connection. High-precision cutting equipment ensures that the length tolerance is within the specified range, while drilling operations ensure accurate hole positioning to meet equipment assembly requirements. |

| Surface Treatment | To improve the corrosion resistance and service life of the aluminum busbars, surface treatment is essential. Common methods include anodizing (to enhance corrosion resistance), tin or silver plating (to improve conductivity), and applying insulating materials (to prevent short circuits and arc discharges). |

| Testing | After production, aluminum busbars undergo rigorous testing to ensure compliance with technical standards. Testing includes conductivity tests (such as eddy current testing to verify electrical performance), dimensional precision measurements (tolerances are usually controlled to ±0.1mm), and dielectric strength tests for insulated busbars (AC withstand voltage tests to ensure the performance of insulation layers). |

Aluminum Busbar Installation Specifications

Connection Method: Bolt compression (apply anti-oxidant), welding (TIG welding), fixture fixation.

Insulation Spacing: Designed according to voltage level, for example, in a 10kV system, phase-to-phase spacing should be ≥125mm.

Thermal Compensation: Leave expansion joints every 20 meters to prevent temperature-induced stress.

Grounding: Multi-point grounding along the entire length to prevent static electricity accumulation.

Aluminum Busbar Standards and Selection

Standards: IEC 61439 (Low Voltage Switchgear Assemblies), ASTM B236 (Aluminum Busbar Standards), GB/T 5585.1-2018 (Conductors for Electrical Engineering), GB 7251 (Low Voltage Switchgear Equipment).

Aluminum Busbar Selection

Current Carrying Capacity: Calculated based on cross-sectional area, ambient temperature, and heat dissipation conditions (e.g., for a 40°C environment, a 100×10mm² aluminum busbar has a current carrying capacity of approximately 1400A).

Short Circuit Endurance: Should meet thermal and dynamic stability requirements for the system’s short circuit current (e.g., 50kA/1s).

Key Parameters for Selection:

- Cross-sectional Size: Determined based on current carrying capacity (e.g., for 1000A, select 80×10mm²) and short circuit endurance (thermal stability check).

- Material: Pure aluminum (1060) or aluminum alloy (6063), with the latter offering higher strength.

- Insulation Grade: Bare busbar (IP00) or fully insulated (IP54 or higher).

Selection Key Points

Current Capacity: Select the cross-sectional area based on load current, leaving a 20%–30% margin.

Environmental Adaptability:

- In humid or corrosive environments, choose coated or insulated busbars.

- In high-temperature environments, consider heat dissipation design (e.g., adding heat sinks).

Installation Method:

- For horizontal installation, consider the bending deformation caused by the busbar's own weight.

- For vertical installation, strengthen support fixtures.

Economic Consideration:

The cost of aluminum busbars is about 30%–50% of copper busbars, and they are lightweight (density 2.7g/cm³), making them suitable for budget-sensitive or weight-reduction scenarios.

Aluminum Busbar vs Copper Busbar Comparison

| Characteristic | Aluminum Busbar | Copper Busbar |

| Electrical Conductivity | 61% IACS (pure aluminum) | 100% IACS |

| Density | 2.7g/cm³ | 8.96g/cm³ |

| Cost | Low (approximately 30% of copper) | High |

| Oxidation Resistance | Prone to oxidation, requires surface treatment | Oxide film has good conductivity and high stability |

| Current Carrying Capacity Ratio | Approximately 78% of copper for the same cross-section | Benchmark |

| Applicable Scenarios | Medium and low-voltage distribution, large cross-sectional area requirements | High-frequency/high-density connections, small-space scenarios |

Aluminum busbars, due to their high cost-performance ratio and adaptability, are key components for high current transmission, especially in scenarios requiring lightweight and large cross-sectional areas. When designing, it is essential to consider electrical performance, mechanical strength, and environmental factors. Proper selection and installation according to standards ensure stable long-term operation.

Typical Issues and Solutions for Aluminum Busbars

| Typical Issue | Solution |

| Corrosion at aluminum-copper connection | Due to the electrochemical properties of aluminum and copper being different, direct connection can lead to galvanic corrosion, damaging the contact point. Solutions include using aluminum-copper transition joints (e.g., joints made using explosive welding or friction welding) or applying tin-plated aluminum busbars to reduce the potential difference between the metals and prevent electrochemical corrosion. |

| Excessive heating of the busbar | Overload, excessive contact resistance, or poor heat dissipation may cause the busbar temperature to rise, affecting system safety. Solutions include increasing the busbar cross-section to reduce current density, adding forced air cooling or natural cooling conditions, applying heat dissipation coatings to improve cooling efficiency, or using busbars with better heat dissipation performance, such as slot or tube-shaped busbars to increase the heat dissipation area. |

| Vibration causes bolt loosening | Mechanical vibrations over time can cause loosening of bolts at aluminum busbar connections, affecting contact stability. Solutions include adding spring washers at the bolt connections to provide continuous tightening force, using thread-locking adhesive to prevent loosening, or using rivets or welding to secure connections to enhance vibration resistance and long-term reliability. |

Aluminum busbars, with their lightweight, low cost, and ease of processing advantages, are key components in low-voltage distribution systems. The design must consider current carrying capacity, mechanical strength, thermal stability, and environmental adaptability. Through standard selection, surface treatment, and installation processes, system reliability and cost-effectiveness can be significantly improved. In high current density or harsh environments, material and structural designs should be optimized accordingly.

Aluminum busbars strike a balance between efficiency, cost savings, and ease of installation. Detailed design includes carefully selecting aluminum alloys, appropriate sizes to compensate for lower conductivity, and protective measures to prevent corrosion and thermal expansion.